CN90

KYA

KYA-CN90

4.10kgs(9.02lbs)

70-120psi(5-8.3bar)

225-275 Nails

15 Degree Flat wire coil nails

| Availability: | |

|---|---|

| Quantity: | |

Product Overview: CN90 Pneumatic Coil Framing Nailer The CN90 is a professional Powerful coil framing nailer, The CN90 can be used for your framing, sheathing, decking, subflooring, exterior deck, crate & box assembly, siding, and furring jobs. ● 360° Multi directional exhaust cover to blow air away from your face. ● Cushioned rubber grip and Ergonomic frame design provide comfort and balance during operation. ● Tough nylon, fast and easy loading magazine of coil nails. ● Tool-Free Depth Adjust to adjust nail countersinking and Trigger Lock for safety. ● Powerful, Rapid Nailing Performance; Ergonomic Design, Well Balanced. ● Durable nose and Anti-abrasive driver for extended tool life. ● Dust cover blocks nails or wire chips. Similar Tool:MAX CN890F Coil Siding Nailer, Bostitch N90C Coil Nailer etc. |

| Model: | CN90 Pneumatic Coil Siding Nailer |

| Air Tool Type: | Air Nailer |

| Tool Diamensions: | 362mmx132mmx307mm(14-1/4"x5-3/16"x12-1/8") |

| Net Tool Weight: | 4.10kgs(9.02lbs) |

| Body Material: | Aluminum Body |

| Operate Pressure: | 70-120psi(5-8.3bar) |

| Load Capacity: | 225-275 Nails |

| Fasteners Type: | 15 Degree Flat wire coil nails |

| Fasteners Head Diameter: | 0.236"(6.0mm)-0.315"(8.0mm) |

| Fasteners Shank Diameter: | 0.113"(2.87mm)-0.131"(3.3mm) |

| Fasteners Length: | 2"(50mm)-3-9/16"(90mm) |

| Fasteners Shank Type: | Smooth,Screw,Ring |

15 Degree Flat wire coil nails Fasteners Head Diameter:0.236"(6.0mm)-0.315"(8.0mm) Fasteners Shank Diameter:0.113"(2.87mm)-0.131"(3.3mm) Fasteners Length:2"(50mm)-3-9/16"(90mm) Fasteners Shank Type:Smooth,Screw,Ring |

Powerful and durable aluminum housing.

Powerful and durable aluminum housing.

Large capacity magazine.

Large capacity magazine.

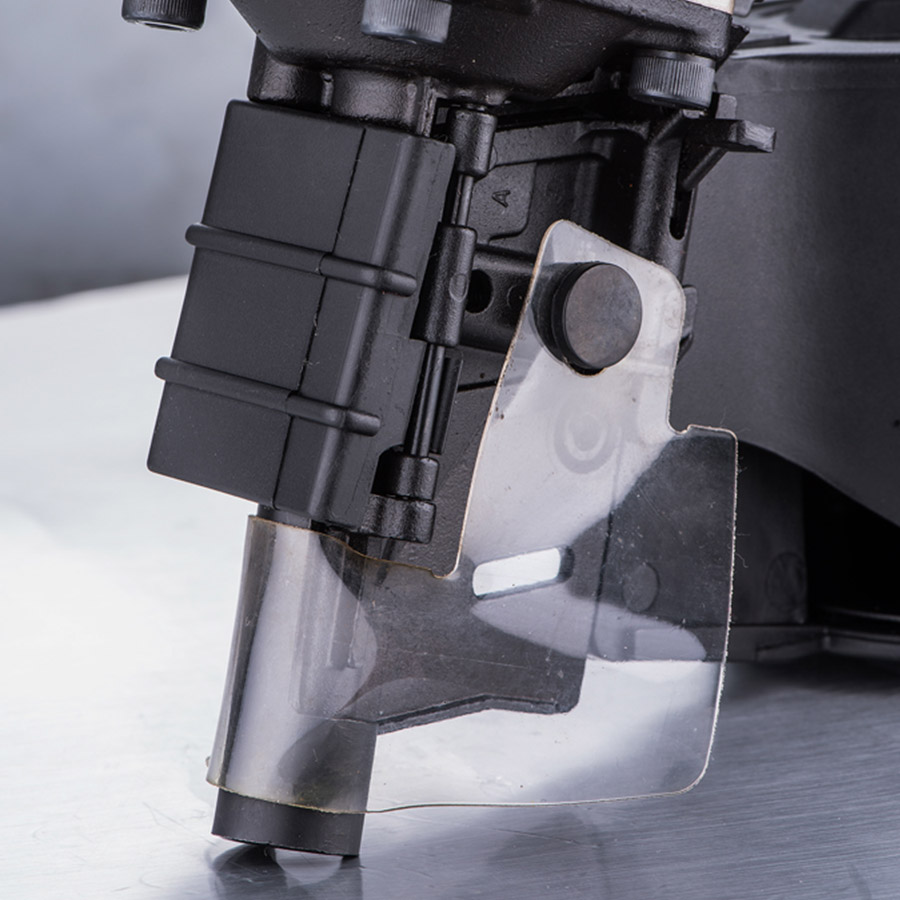

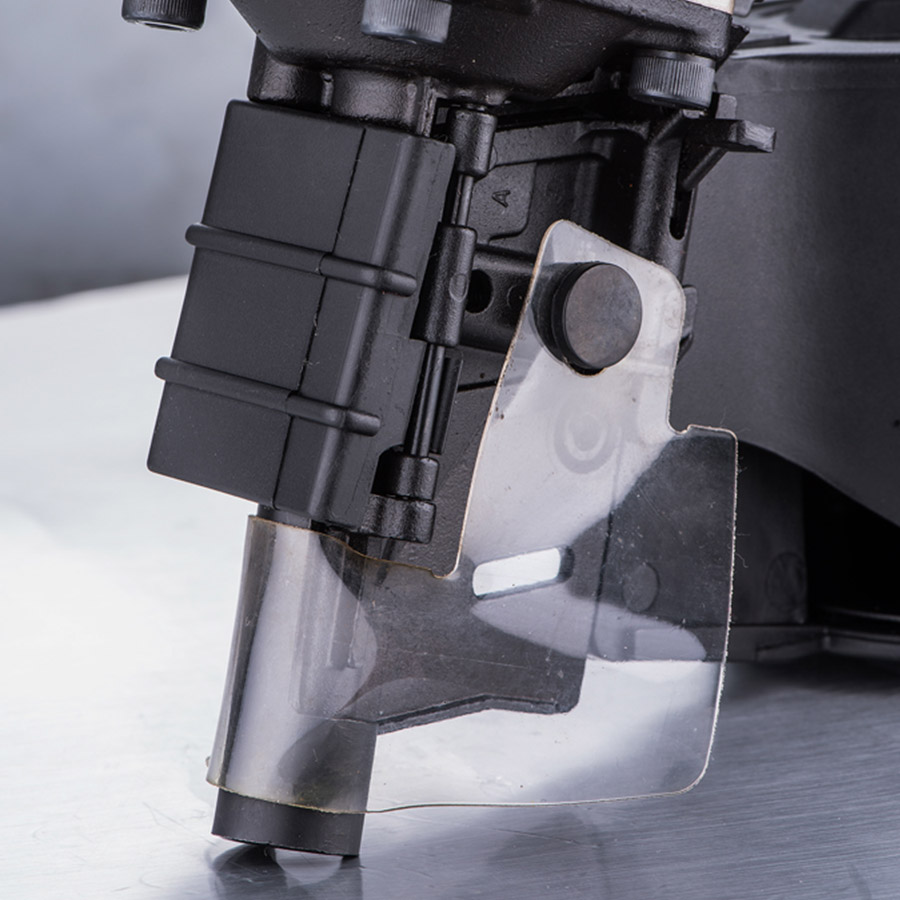

Heat treated nose with long service life.

Heat treated nose with long service life.

Safety guard prevents nail or small block hurting people wehile nailing.

Safety guard prevents nail or small block hurting people wehile nailing.

Light weight with comfortable rubber grip.

Light weight with comfortable rubber grip.

Most powerful nailing make happy working.

Most powerful nailing make happy working.

Easily rotate the exhaust port a full 360 degree to control the direction of the outputted air.

Easily rotate the exhaust port a full 360 degree to control the direction of the outputted air.

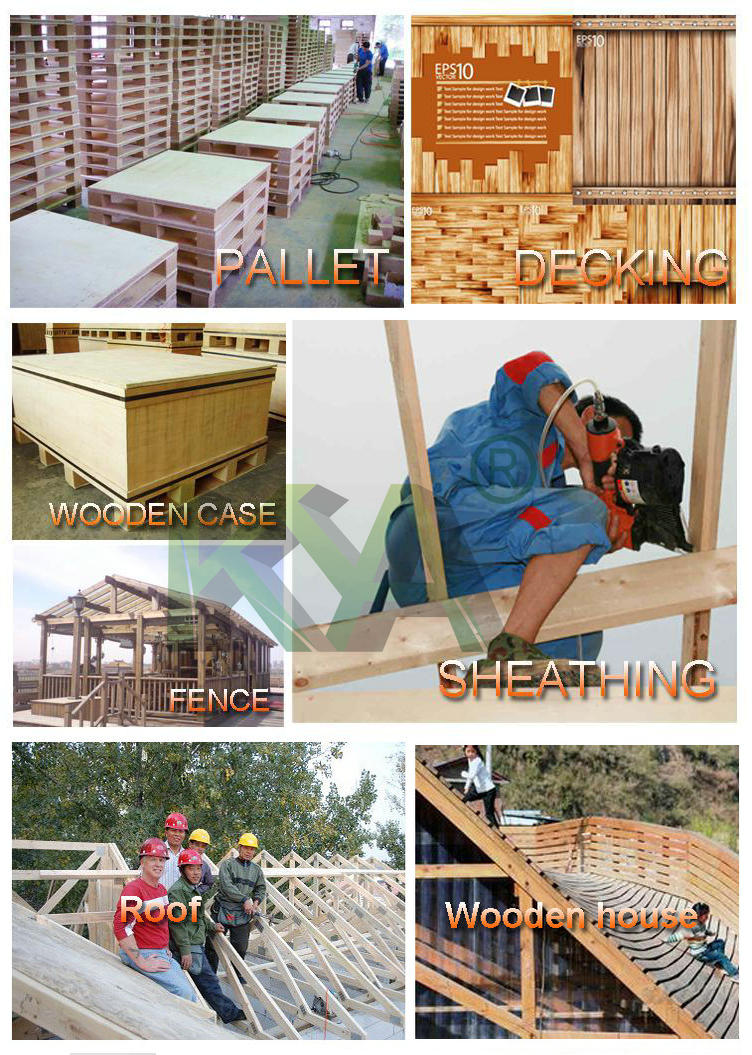

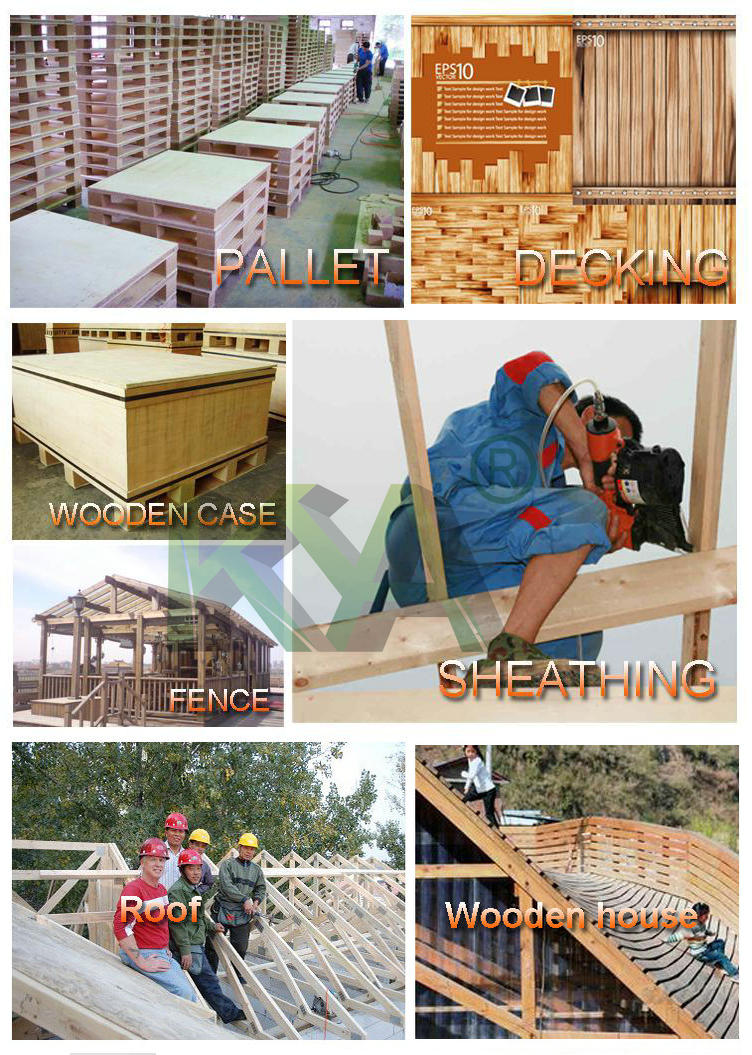

Assembly and repair of pallets,drums,export wooden boxes.

Wooden fencing.

Crating.

General construction applications including:Siding,decking and sheathing.

Framing and cubflooring.

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

| 3 | Work weakly and sluggishly | 1. Worn or damaged piston o-ring | Check and replace piston o-ring | |

| 2.Inadequate lubrication for head valve piston o-rings or too tight head valve piston o-rings | Place 2 or 6 drops of oil on o-rings or replace head valve piston o-rings | |||

| 3.Dirt in the nozzle | Check and clean the nozzle | |||

| 4 | Tool jams frequently | 1.Damaged or Worn driver (piston unit) | Check and replace driver (piston unit) | |

| 2.Damaged or Worn driver guide (nose) | Check and replace driver guide (nose) | |||

| 3.Driver guide cover is bent,so the space between driver guide cover and driver guide is too big | Check and replace driver guide cover | |||

| 5 | Nail can not be shot | 1. Driver (piston unit) can't return to the correct position. | Refer to no. 1 Symptom | |

| 2.Driver guide(nose) can not match magazine well | Check and correct the position between driver guide(nose) and magazine | |||

| 3.Worn or damaged nail pusher compression spring | Check and replace nail pusher compression spring | |||

Product Overview: CN90 Pneumatic Coil Framing Nailer The CN90 is a professional Powerful coil framing nailer, The CN90 can be used for your framing, sheathing, decking, subflooring, exterior deck, crate & box assembly, siding, and furring jobs. ● 360° Multi directional exhaust cover to blow air away from your face. ● Cushioned rubber grip and Ergonomic frame design provide comfort and balance during operation. ● Tough nylon, fast and easy loading magazine of coil nails. ● Tool-Free Depth Adjust to adjust nail countersinking and Trigger Lock for safety. ● Powerful, Rapid Nailing Performance; Ergonomic Design, Well Balanced. ● Durable nose and Anti-abrasive driver for extended tool life. ● Dust cover blocks nails or wire chips. Similar Tool:MAX CN890F Coil Siding Nailer, Bostitch N90C Coil Nailer etc. |

| Model: | CN90 Pneumatic Coil Siding Nailer |

| Air Tool Type: | Air Nailer |

| Tool Diamensions: | 362mmx132mmx307mm(14-1/4"x5-3/16"x12-1/8") |

| Net Tool Weight: | 4.10kgs(9.02lbs) |

| Body Material: | Aluminum Body |

| Operate Pressure: | 70-120psi(5-8.3bar) |

| Load Capacity: | 225-275 Nails |

| Fasteners Type: | 15 Degree Flat wire coil nails |

| Fasteners Head Diameter: | 0.236"(6.0mm)-0.315"(8.0mm) |

| Fasteners Shank Diameter: | 0.113"(2.87mm)-0.131"(3.3mm) |

| Fasteners Length: | 2"(50mm)-3-9/16"(90mm) |

| Fasteners Shank Type: | Smooth,Screw,Ring |

15 Degree Flat wire coil nails Fasteners Head Diameter:0.236"(6.0mm)-0.315"(8.0mm) Fasteners Shank Diameter:0.113"(2.87mm)-0.131"(3.3mm) Fasteners Length:2"(50mm)-3-9/16"(90mm) Fasteners Shank Type:Smooth,Screw,Ring |

Powerful and durable aluminum housing.

Powerful and durable aluminum housing.

Large capacity magazine.

Large capacity magazine.

Heat treated nose with long service life.

Heat treated nose with long service life.

Safety guard prevents nail or small block hurting people wehile nailing.

Safety guard prevents nail or small block hurting people wehile nailing.

Light weight with comfortable rubber grip.

Light weight with comfortable rubber grip.

Most powerful nailing make happy working.

Most powerful nailing make happy working.

Easily rotate the exhaust port a full 360 degree to control the direction of the outputted air.

Easily rotate the exhaust port a full 360 degree to control the direction of the outputted air.

Assembly and repair of pallets,drums,export wooden boxes.

Wooden fencing.

Crating.

General construction applications including:Siding,decking and sheathing.

Framing and cubflooring.

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

| 3 | Work weakly and sluggishly | 1. Worn or damaged piston o-ring | Check and replace piston o-ring | |

| 2.Inadequate lubrication for head valve piston o-rings or too tight head valve piston o-rings | Place 2 or 6 drops of oil on o-rings or replace head valve piston o-rings | |||

| 3.Dirt in the nozzle | Check and clean the nozzle | |||

| 4 | Tool jams frequently | 1.Damaged or Worn driver (piston unit) | Check and replace driver (piston unit) | |

| 2.Damaged or Worn driver guide (nose) | Check and replace driver guide (nose) | |||

| 3.Driver guide cover is bent,so the space between driver guide cover and driver guide is too big | Check and replace driver guide cover | |||

| 5 | Nail can not be shot | 1. Driver (piston unit) can't return to the correct position. | Refer to no. 1 Symptom | |

| 2.Driver guide(nose) can not match magazine well | Check and correct the position between driver guide(nose) and magazine | |||

| 3.Worn or damaged nail pusher compression spring | Check and replace nail pusher compression spring | |||