1010F

KYA

KYA-1010F

0.90kgs

60-100psi (4-7bar)

100 staples

22 Guage 10 Series Fine Wire Staples

| Availability: | |

|---|---|

| Quantity: | |

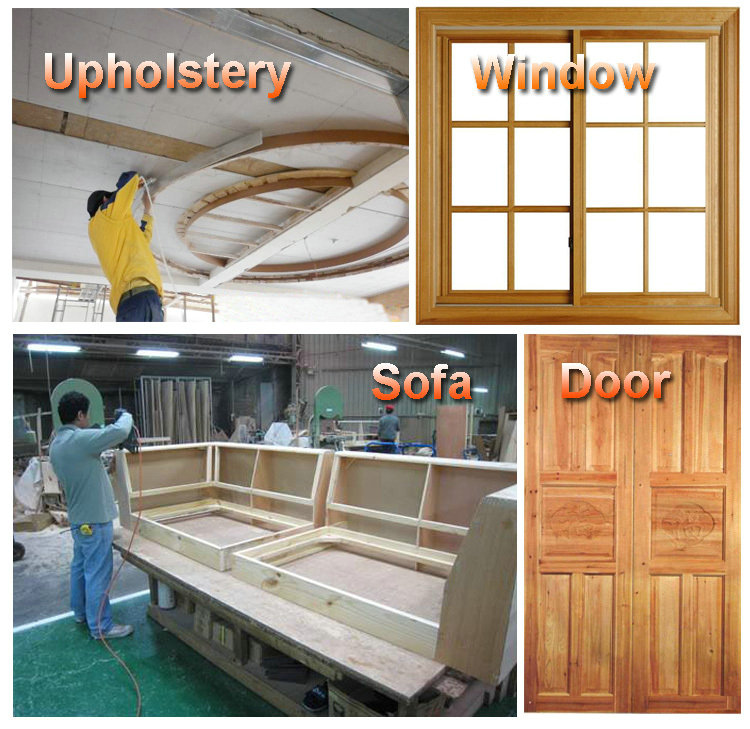

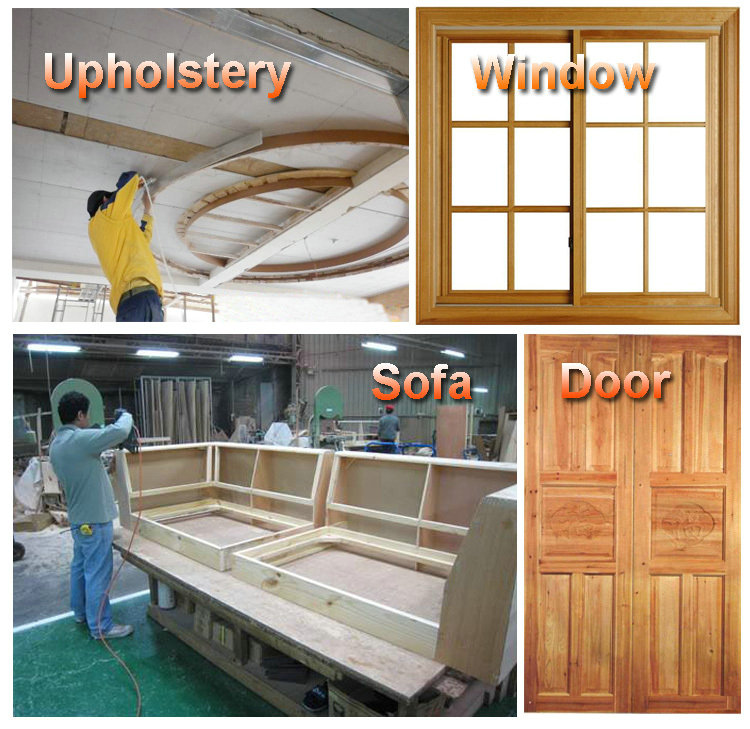

22 Gauge Fine Wire Stapler 1010F22 Gauge Fine Wire Stapler 1010F. Drives 7/16" Crown, 22GA, 1/4", 5/16", 3/8" leg ength staples.This fine wire staple gun is ideal for upholstery, automotive vinyl and other fabric projects. ● Comfortable rubber grip. ● Lengthened thin muzzle design, operation more flexible and convenient. ● Quick release magazine for easy loading. ● Ergonomically engineered body. ● 360° adjustable exhaust. ● Pressure operation of 60 to 100 PSI. |

| Model: | 22 Gauge Fine Wire Stapler 1010F |

| Air Tool Type: | Air Stapler |

| Tool Diamensions: | 200mm x 45mm x 150mm |

| Net Tool Weight: | 0.90kgs (1.98 lbs) |

| Operate Pressure: | 60-100psi (4-7bar) |

| Load Capacity: | 100 staples |

| Staples Type: | 22 Guage 10 Series Fine Wire Staples |

| Staples Crown: | 7/16"(11.2mm) |

| Staples Shank Diameter: | 0.030"(0.75mm) x 0.020"(0.50mm) |

| Staples Length: | 1/5"(5mm)~3/8"(10mm) |

| 22 Guage 10 Series Fine Wire Staples |

| Staples Crown:7/16"(11.20mm) |

| Staples Shank Diameter:0.030"(0.75mm) x 0.020"(0.50mm) |

| Staples Length:1/5"(5mm)~3/8"(10mm) |

Lightweight and well balanced for easy operating.

Lightweight and well balanced for easy operating.

Superior power with hardened one piece for professional application.

Superior power with hardened one piece for professional application.

Open nose design for easy extraction of a jammed nail.

Open nose design for easy extraction of a jammed nail.

Tool free depth of drive adjustment for flush or countersunk drive into varying material.

Tool free depth of drive adjustment for flush or countersunk drive into varying material.

Hardened claw tip, reduces wear and limits slippage when driving at a stand angle.

Hardened claw tip, reduces wear and limits slippage when driving at a stand angle.

Furniture.

Cloth.

Picture frames.

Decoration.

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

22 Gauge Fine Wire Stapler 1010F22 Gauge Fine Wire Stapler 1010F. Drives 7/16" Crown, 22GA, 1/4", 5/16", 3/8" leg ength staples.This fine wire staple gun is ideal for upholstery, automotive vinyl and other fabric projects. ● Comfortable rubber grip. ● Lengthened thin muzzle design, operation more flexible and convenient. ● Quick release magazine for easy loading. ● Ergonomically engineered body. ● 360° adjustable exhaust. ● Pressure operation of 60 to 100 PSI. |

| Model: | 22 Gauge Fine Wire Stapler 1010F |

| Air Tool Type: | Air Stapler |

| Tool Diamensions: | 200mm x 45mm x 150mm |

| Net Tool Weight: | 0.90kgs (1.98 lbs) |

| Operate Pressure: | 60-100psi (4-7bar) |

| Load Capacity: | 100 staples |

| Staples Type: | 22 Guage 10 Series Fine Wire Staples |

| Staples Crown: | 7/16"(11.2mm) |

| Staples Shank Diameter: | 0.030"(0.75mm) x 0.020"(0.50mm) |

| Staples Length: | 1/5"(5mm)~3/8"(10mm) |

| 22 Guage 10 Series Fine Wire Staples |

| Staples Crown:7/16"(11.20mm) |

| Staples Shank Diameter:0.030"(0.75mm) x 0.020"(0.50mm) |

| Staples Length:1/5"(5mm)~3/8"(10mm) |

Lightweight and well balanced for easy operating.

Lightweight and well balanced for easy operating.

Superior power with hardened one piece for professional application.

Superior power with hardened one piece for professional application.

Open nose design for easy extraction of a jammed nail.

Open nose design for easy extraction of a jammed nail.

Tool free depth of drive adjustment for flush or countersunk drive into varying material.

Tool free depth of drive adjustment for flush or countersunk drive into varying material.

Hardened claw tip, reduces wear and limits slippage when driving at a stand angle.

Hardened claw tip, reduces wear and limits slippage when driving at a stand angle.

Furniture.

Cloth.

Picture frames.

Decoration.

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||