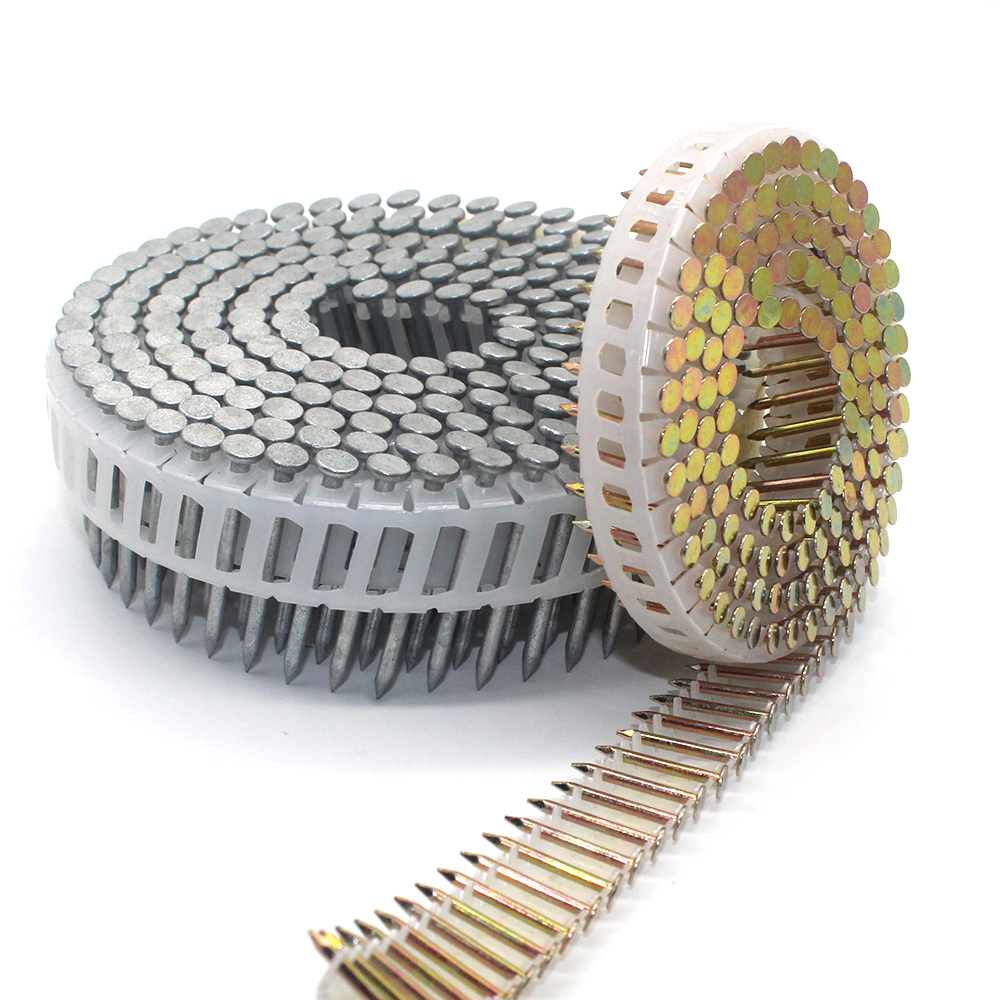

15° Electro-Galvanized Plastic Sheet Coil Nails (1.8×18mm)

![Electro-Galvanized 1.8×18mm 15 Degree Plastic Sheet Coil Nails - KYA Fasteners]()

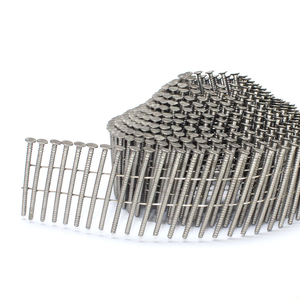

KYA Fasteners, a 20+ year factory, manufactures 15° plastic sheet coil nails for siding, sheathing, decking. 1.8×18mm, electro-galvanized, full round head. Fits MAX, Hitachi, Bostitch, Senco. 300 pcs/coil. Exported to USA, Canada, Germany, Australia and 50+ countries.

![15° Coil Nail Plastic Sheet Collation Close-Up]()

Why Choose KYA Plastic Sheet Coil Nails?

Factory direct – 20+ years OEM experience

Plastic sheet collation – no debris, clean nailing

15° wire angle – fits major coil nailers

300 pcs/coil – high capacity, less reload

Global shipping: USA, EU, AU, CA in 20–30 days

Request a Quote

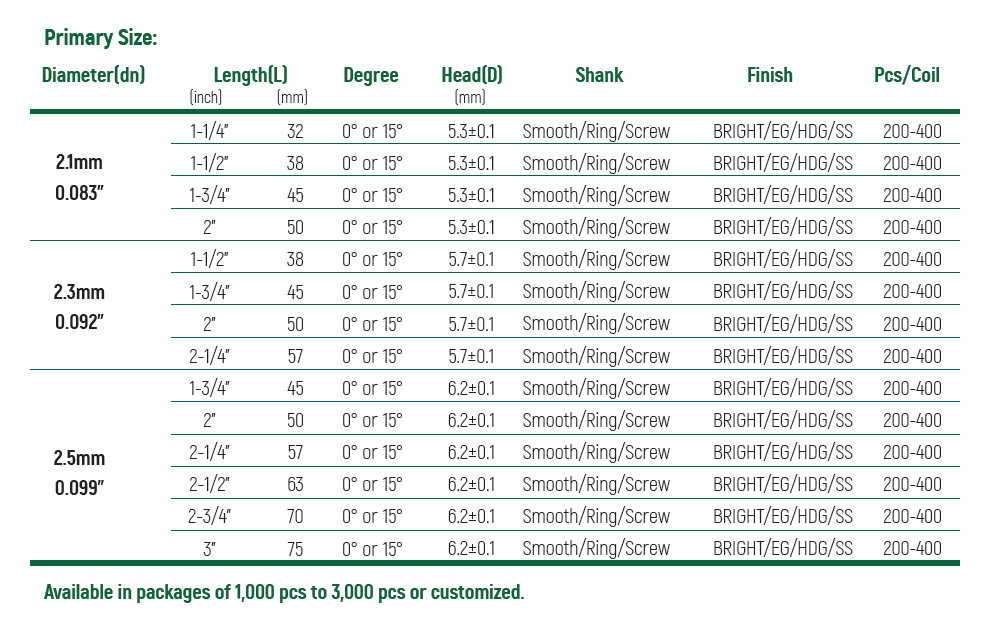

Product Specifications

Coil Nail Specs

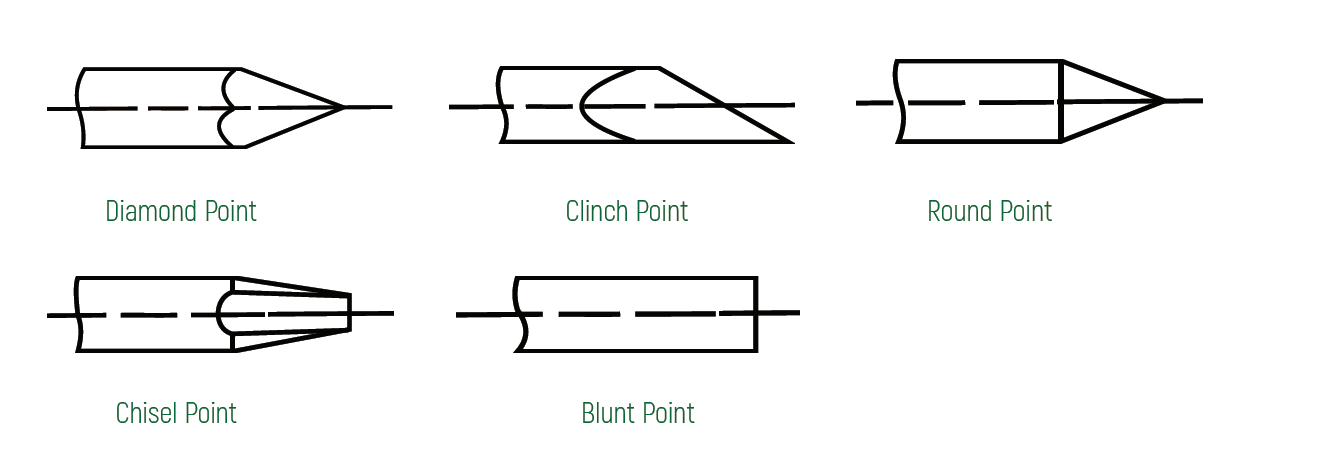

![Diamond Point]()

Nail Point

![Smooth Shank]()

Nail Shank

![Full Round Head]()

Nail Head

| Parameter | Specification |

| Nail Length | 22–100mm (7/8"–4") |

| Wire Diameter | 1.8–4.0mm (0.071"–0.157") |

| Head Diameter | 5.0–9.2mm (0.195"–0.362") |

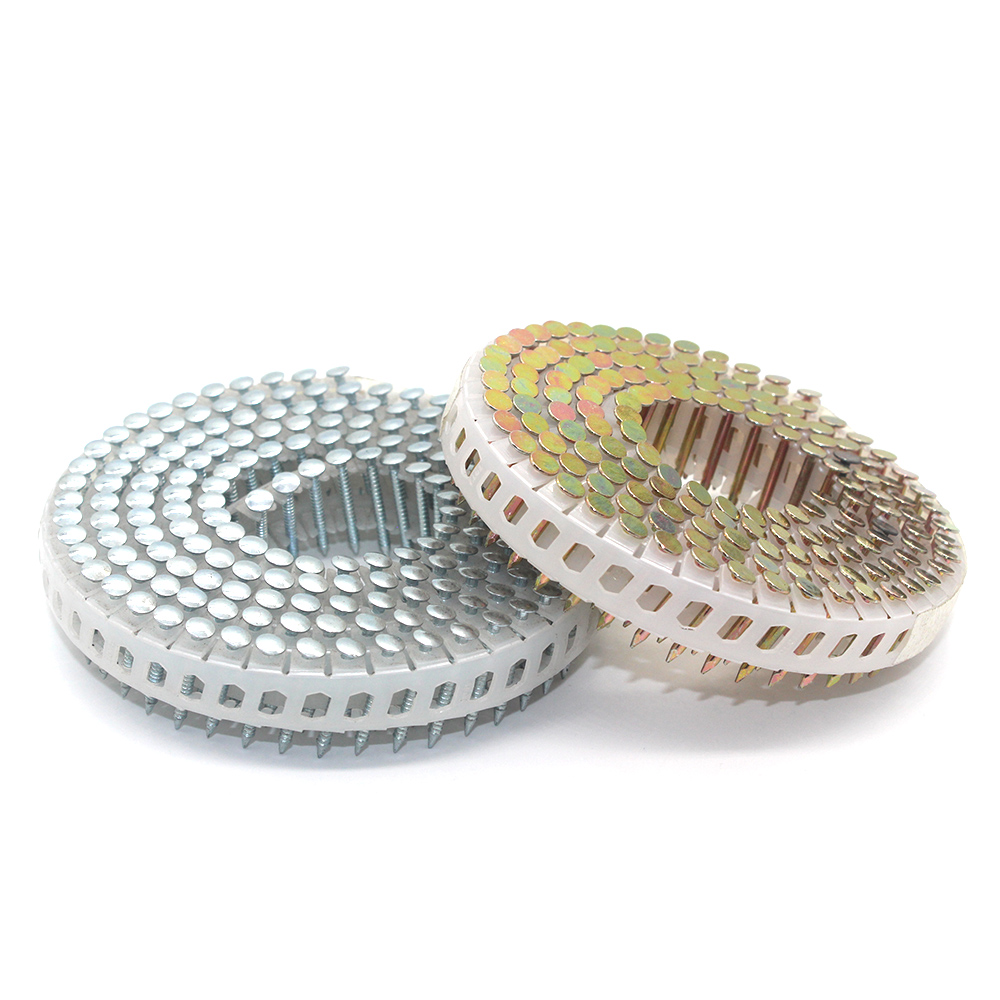

| Collation Type | Plastic Sheet (Virgin Plastic) |

| Coil Capacity | 50–300 pcs/coil |

| Angle | 15° (0° available) |

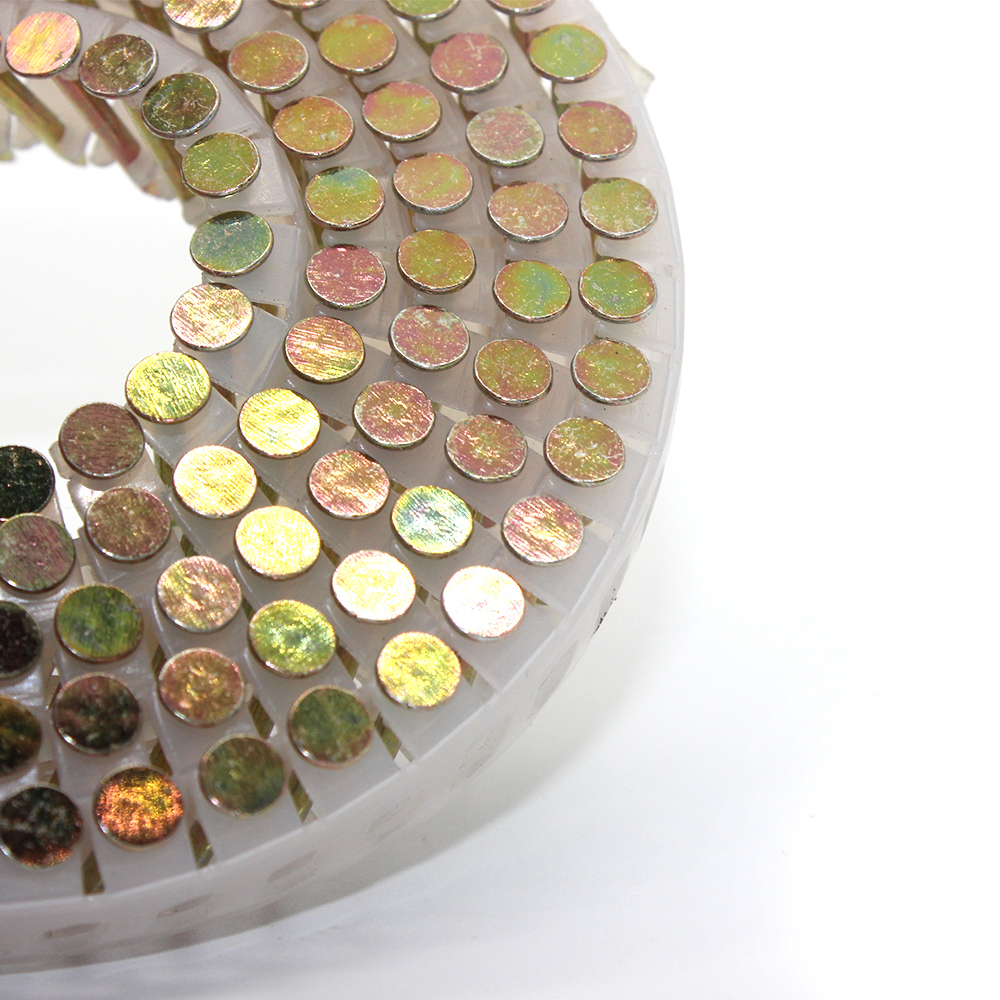

| Finish | Electro-Galvanized |

| Material | #45 Steel |

![Nail Point Types: Diamond, Chisel, Blunt]()

![Shank Types: Smooth, Screw, Ring]()

![Coil Nail Size Chart]()

Point: Diamond, Chisel, Blunt, Clinch, Round

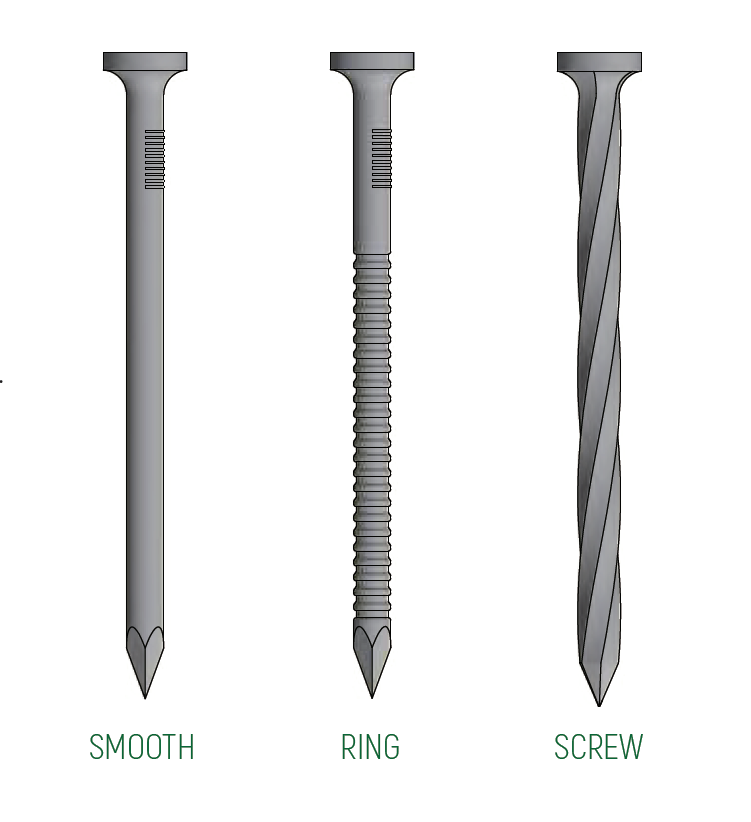

Shank: Smooth, Screw, Ring

Head: Full Round, Smooth/Checkered

Fits Tools: MAX CN55, Hitachi NV65AH, Bostitch N80CB, Senco SCN65

Request a Quote Features

Plastic Sheet Coil Nail Features

Virgin plastic sheet — no debris, clean job site

15° wire collation — fits all major coil nailers

Full round head — superior holding power

Electro-galvanized — indoor/outdoor corrosion resistance

High capacity coils — 300 pcs, less downtime

Applications

Where Are Plastic Sheet Coil Nails Used?

Siding installation – vinyl, fiber cement

Roof sheathing – plywood, OSB

Subfloor & decking – structural framing

Fencing & crating – pallets, packaging

Framing & carpentry – light to medium duty

![Coil Nails in Siding and Sheathing]() Explore All Coil Nails

Explore All Coil Nails Frequently Asked Questions

Coil Nail FAQ

What is plastic sheet collation?

Nails are held by flexible plastic strips — detaches cleanly during nailing, no debris, ideal for siding & sheathing.

15° vs 0° coil nails?

15°: Fits most coil nailers (MAX, Bostitch). 0°: For specific straight-feed tools.

Best for outdoor use?

Electro-galvanized: Good for sheltered exterior. Use HDG or SS near coasts.

How many nails per coil?

50–300 pcs — 300 pcs standard for high-volume jobs.

Compatible nailers?

MAX CN55/70, Hitachi NV65, Bostitch N80CB, Senco SCN65 — 15° plastic sheet coil.

Ask a Question About KYA Fasteners

KYA Fasteners – Plastic Sheet Coil Nail Factory

Since 2003, KYA Fasteners has produced 15° plastic sheet coil nails for roofers, framers, siding contractors in USA, Canada, Germany, Australia and 50+ countries. All nails use virgin plastic collation, #45 steel, and electro-galvanized finish.

Export: 50+ countries

Finish: EG, HDG, SS, Aluminum, Bright

OEM: Custom length, diameter, head, point

MOQ: 500 coils

Need plastic sheet coil nails? Get a quote from KYA today.

Contact Us English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa