Book Binding Wire for Manuals and Notebooks

KYA Fasteners’ book binding wire offers versatile solutions for creating durable, professional-looking books that lay flat. Available in Wire-O, plastic coil, and plastic comb binding, these options are cost-effective and suitable for manuals, school agendas, cookbooks, calendars, and notebooks. Each binding type provides unique benefits, such as durability, flexibility, and the ability to add or remove pages, ensuring perfect alignment and a polished finish for various binding needs.

![Book binding wire for notebooks and manuals]()

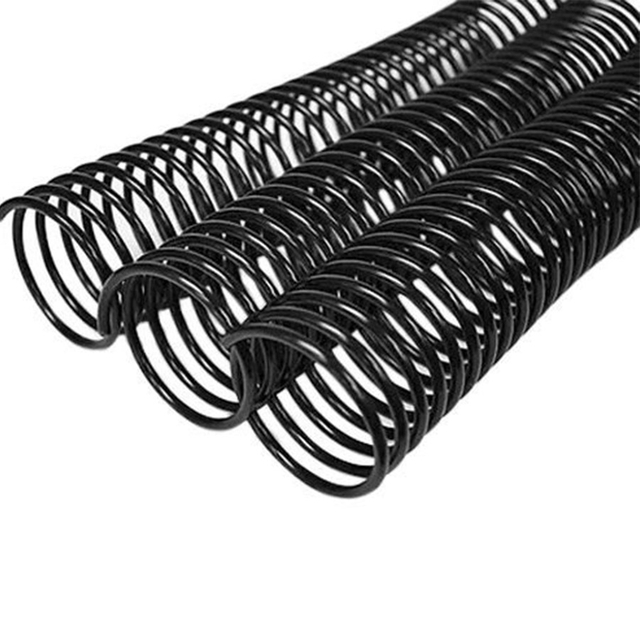

Wire-O Binding Features

Wire-O binding uses a double wire to create a continuous hinge, securing book covers and pages. It offers durability, allows books to lay flat or fold over completely, and hides connectors for a polished look. Facing pages align perfectly, making it ideal for professional documents and notebooks.

Durable double-wire construction

Allows books to lay flat or fold over

Hidden connectors for a polished finish

Perfect page alignment for professional results

Cost-effective for various binding needs

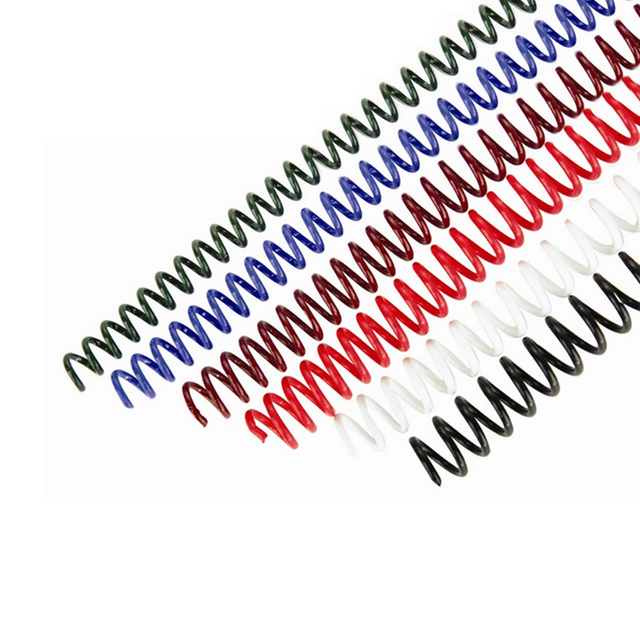

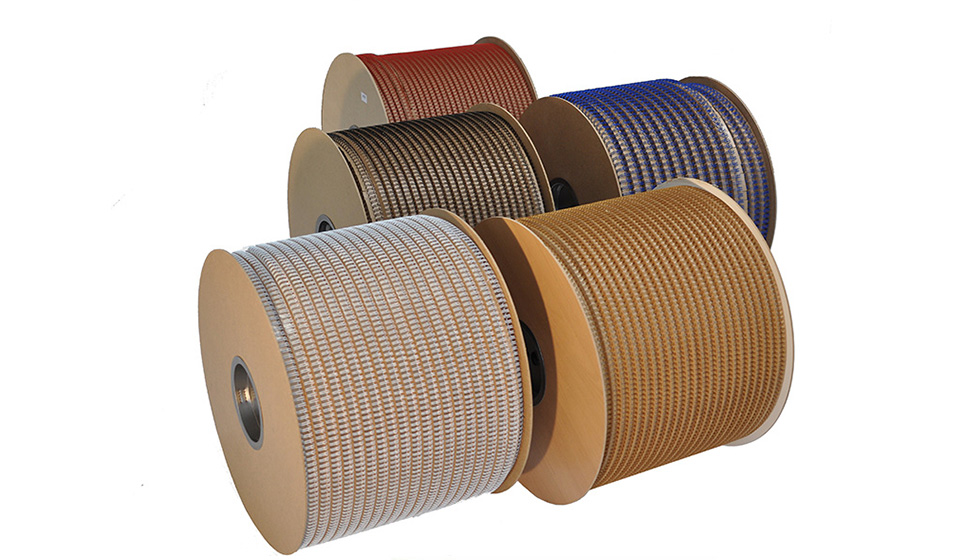

Plastic Coil Spiral Binding Features

Plastic coil spiral binding runs through closely spaced holes near the gutter margin, offering a crushproof, durable, and modern look. Available in multiple colors, sizes, and pitches, it is an economical choice for high-volume binding projects.

Crushproof and durable design

Multiple color, size, and pitch options

Modern, clean aesthetic

Economical for large-scale binding

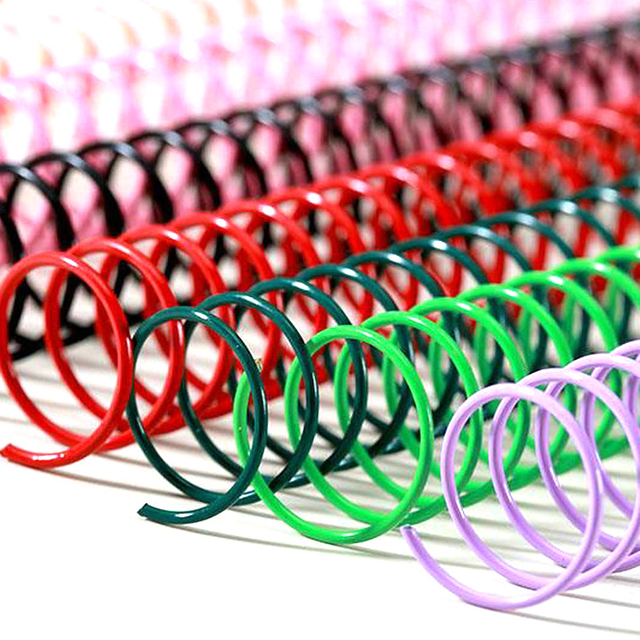

Plastic Comb Binding Features

Plastic comb binding uses a filament with regularly spaced teeth that can be opened to insert or remove pages, making it ideal for documents that require updates. It supports spine imprinting, comes in multiple colors, and ensures page alignment.

Easy to open for adding or removing pages

Supports spine imprinting for customization

Available in multiple colors

Ensures perfect page alignment

Cost-effective for short runs

Coil vs. Comb Binding: Key Differences

Coil and comb binding differ in flexibility and durability. Comb binding allows easy page additions or removals without destroying the binding, making it ideal for documents that change frequently. Coil binding, however, is more durable, with no moving parts and smaller round holes for less wear and tear, suitable for books needing long-term durability.

Comb binding: Easy to modify pages, cost-effective for updates

Coil binding: More durable, ideal for long-lasting books

Frequently Asked Questions About Book Binding Wire

What is book binding wire used for?

It is used for binding manuals, school agendas, cookbooks, calendars, and notebooks, ensuring pages lay flat and align perfectly.

What is the difference between Wire-O, coil, and comb binding?

Wire-O uses double wire for durability and a polished look; coil is crushproof with a modern aesthetic; comb allows easy page updates.

Which binding type is best for documents that need updates?

Comb binding is ideal for documents requiring page additions or removals due to its openable design.

Which binding type is more durable?

Coil binding is more durable, with no moving parts and smaller holes for less wear and tear.

Are there color options for binding wire?

Yes, plastic coil and comb binding are available in multiple colors for customization.

Is book binding wire cost-effective?

Yes, all three binding types (Wire-O, coil, comb) are economical, especially for short runs and high-volume projects.

About KYA Fasteners for Binding Solutions

With over 20 years of expertise, KYA Fasteners is a trusted global supplier of high-quality fasteners and binding solutions, delivering reliable products for a wide range of applications worldwide. Request a Quote to explore our comprehensive product range.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa