Bright Finish

Bright fasteners have no coating to protect the steel and are susceptible to corrosion if exposed to high humidity or water. They are not recommended for exterior use or in treated lumber, and only for interior applications where no corrosion protection is needed. Bright fasteners are often used for interior framing, trim and finish applications.

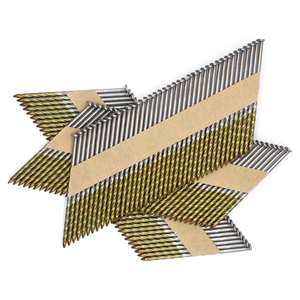

Hot Dip Galvanized (HDG)

Hot dip galvanized fasteners are coated with a layer of Zinc to help protect the steel from corroding. Although hot dip galvanized fasteners will corrode over time as the coating wears, they are generally good for the lifetime of the application. Hot dip galvanized fasteners are generally used for outdoor applications where the fastener is exposed to daily weather conditions such as rain and snow. Areas near the coasts where the salt content in rain water is much higher, should consider Stainless Steel fasteners as salt accelerates the deterioration of the galvanization and will accelerate corrosion.

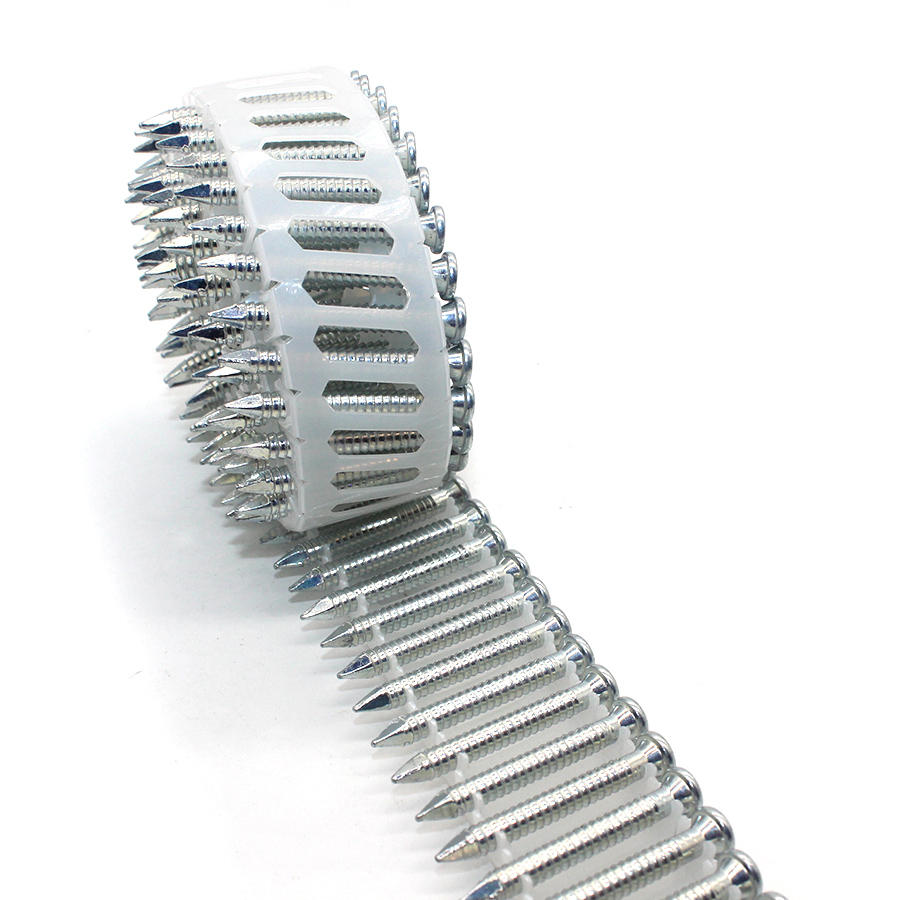

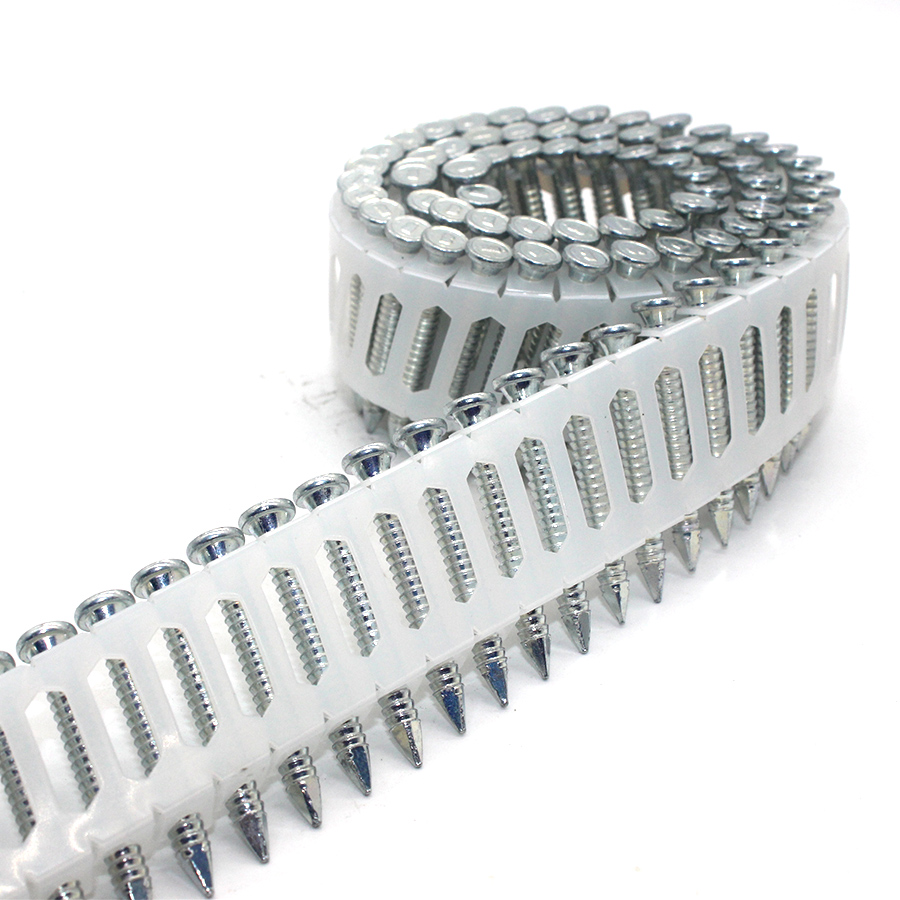

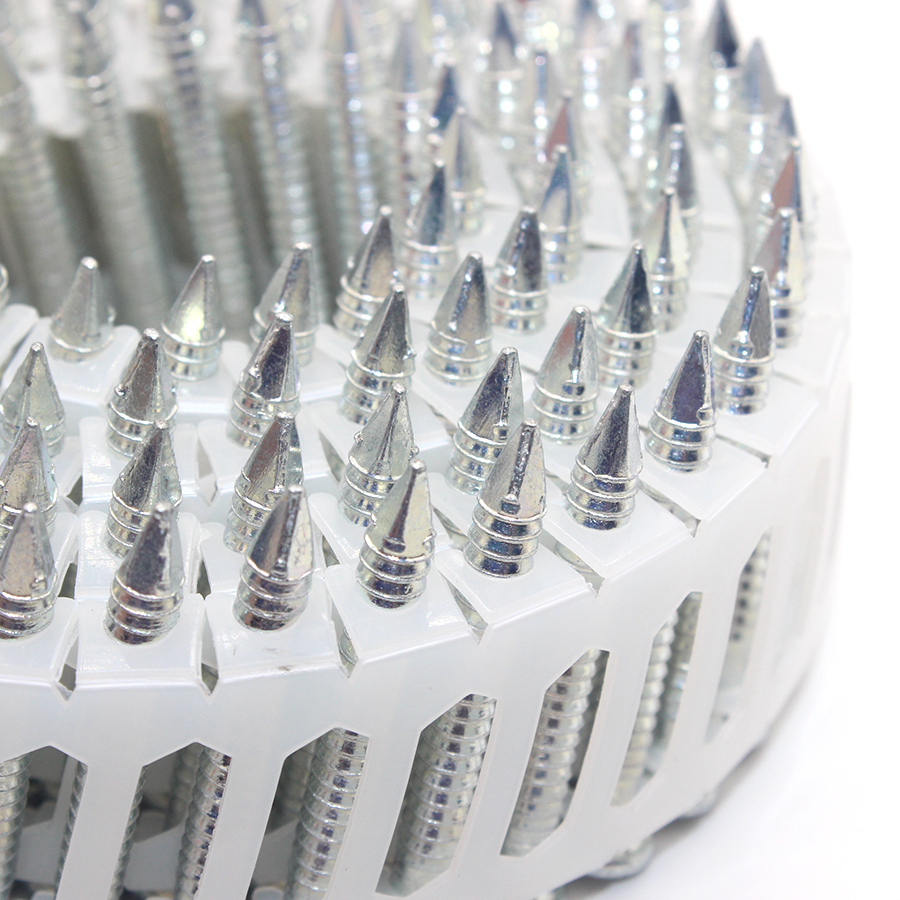

Electro Galvanized (EG)

Electro Galvanized fasteners have a very thin layer of Zinc that offers some corrosion protection. They are generally used in areas where minimal corrosion protection is needed such as bathrooms, kitchens and other areas that are susceptible to some water or humidity. Roofing nails are electro galvanized because they are generally replaced before the fastener begins to wear and are not exposed to harsh weather conditions if installed properly. Areas near the coasts where salt content in rain water is higher should consider a Hot Dip Galvanized or Stainless Steel fastener.

Stainless Steel (SS)

Stainless steel fasteners offer the best corrosion protection available. The steel may oxidize or rust over time but it will never lose its strength from corrosion. Stainless Steel fasteners can be used for exterior or interior applications and generally come in 304 or 316 stainless steel.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa