Overview

Self-Drilling Drywall Screws 3.5mm x 25mm

![KYA Fasteners Self-Drilling Drywall Screws Self-Drilling Drywall Screws]()

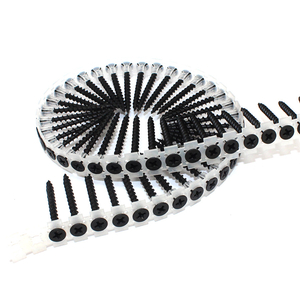

KYA Fasteners' Self-Drilling Drywall Screws 3.5mm x 25mm are engineered for efficient installation in drywall, cement board, and hardie board applications. Made from C1022A steel with a bugle head, these collated screws feature a Duraspin design for easy spinning and strong attachments. Available in black phosphating, grey phosphating, yellow zinc, or blue-white zinc finishes, they offer corrosion resistance for indoor use. Compatible with leading collated screw guns like Makita, Hilti, Senco, Festool, Hitachi, Ridgid, and Bosch, each box contains 1,000 screws, ideal for drywall installation, furniture building, and framing projects.

![3.5mm x 25mm Drywall Screws Collated Drywall Screws]()

![Self-Drilling Screws in Drywall Installation Drywall Screws in Use]()

Key Features of Self-Drilling Drywall Screws

Bugle head for strong hold on drywall and composite materials

Duraspin design for easy spinning and secure fastening

Collated belt compatible with major screw gun brands

C1022A steel with multiple corrosion-resistant finishes

Self-drilling tip for efficient installation

Request a Quote Product Specifications

Detailed Specifications for Self-Drilling Drywall Screws

| Size (mm) | Box Size (cm) | Carton Size (cm) | Box Volume | Carton Volume | Pallet Volume | Weight (g/screw) |

| 3.5 x 25 | 56 x 26 x 3 | 57 x 27 x 16.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 1.27 |

| 3.5 x 30 | 56 x 26 x 4 | 57 x 27 x 21.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 1.55 |

| 3.5 x 32 | 56 x 26 x 4 | 57 x 27 x 21.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 1.6 |

| 3.5 x 35 | 56 x 26 x 4 | 57 x 27 x 21.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 1.67 |

| 3.5 x 38 | 56 x 26 x 5 | 57 x 27 x 26.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 1.86 |

| 3.5 x 42 | 56 x 26 x 5 | 57 x 27 x 26.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 1.99 |

| 3.5 x 45 | 56 x 26 x 5 | 57 x 27 x 26.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 2.1 |

| 3.5 x 50 | 56 x 26 x 6 | 57 x 27 x 31.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 2.42 |

| 3.5 x 55 | 56 x 26 x 6 | 57 x 27 x 31.5 | 1,000 pcs | 10,000 pcs | 240,000 pcs | 2.5 |

| 3.5 x 60 | 56 x 26 x 8 | 57 x 27 x 25.5 | 1,000 pcs | 6,000 pcs | 108,000 pcs | 2.89 |

| 3.5 x 75 | 56 x 26 x 8 | 57 x 27 x 25.5 | 1,000 pcs | 6,000 pcs | 108,000 pcs | 3.3 |

| Attribute | Details |

| Model | Self-Drilling Drywall Screws |

| Primary Size | 3.5mm x 25mm (0.138" x 1") |

| Material | C1022A Steel |

| Head Type | Bugle Head |

| Surface Finish | Black Phosphating, Grey Phosphating, Yellow Zinc, Blue-White Zinc |

| Fitting Tools | Makita, Hilti, Senco, Festool, Hitachi, Ridgid, Bosch, other collated screw guns |

| Collation | Plastic Belt |

The Self-Drilling Drywall Screws are optimized for drywall, cement board, and furniture applications. Contact KYA Fasteners for bulk orders or custom specifications.

Request a Bulk Quote Finishes

Finishes for Self-Drilling Drywall Screws

Black Phosphating

Provides corrosion resistance and a sleek finish, ideal for indoor drywall applications.

Grey Phosphating

Offers corrosion protection and a neutral aesthetic for drywall and composite materials.

Yellow Zinc

Zinc coating for moderate corrosion resistance, suitable for low-humidity environments.

Blue-White Zinc

Zinc-plated finish for enhanced corrosion resistance, ideal for indoor applications.

Applications

Applications for Self-Drilling Drywall Screws

The Self-Drilling Drywall Screws are designed for secure fastening in drywall and construction projects using collated screw guns.

Explore Related Screws Frequently Asked Questions

FAQs About Self-Drilling Drywall Screws

What are these screws used for?

They are used for drywall installation, cement or hardie board fastening, furniture building, decks, steps, and framing.

Which tools are compatible with these screws?

They are compatible with collated screw guns from Makita, Hilti, Senco, Festool, Hitachi, Ridgid, Bosch, and other brands.

What is the benefit of the bugle head design?

The bugle head provides a stronger hold on drywall and composite materials, ensuring flush installation.

What finishes are available?

Available finishes include black phosphating, grey phosphating, yellow zinc, and blue-white zinc.

How many screws are in a box?

Each box contains 1,000 screws, with 10,000 per carton.

Can I request a sample of these screws?

Yes, contact KYA Fasteners to arrange a sample to test the screws’ quality.

Ask a Question About KYA Fasteners

Why Choose KYA Fasteners for Self-Drilling Drywall Screws?

With over 20 years of expertise, KYA Fasteners is a trusted leader in industrial fasteners, delivering high-quality Self-Drilling Drywall Screws. Our SGS-certified production ensures precision and durability, serving clients in over 50 countries. We ship from Qingdao port within 20-30 days, offering customized solutions for drywall and construction needs.

Global Reach: Exporting to 50+ countries with reliable screws

Premium Quality: Durable, corrosion-resistant fasteners for professional use

Fast Delivery: Ships worldwide in 20-30 days from Qingdao port

Custom Solutions: Tailored sizes and finishes for specific projects

Enhance your construction projects with Self-Drilling Drywall Screws. Request a free quote today to experience KYA's quality and service.

Contact KYA Fasteners English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa