![KYA-Z94 Nail Making Machine KYA-Z94 Automatic Control Common Nail Making Machine]()

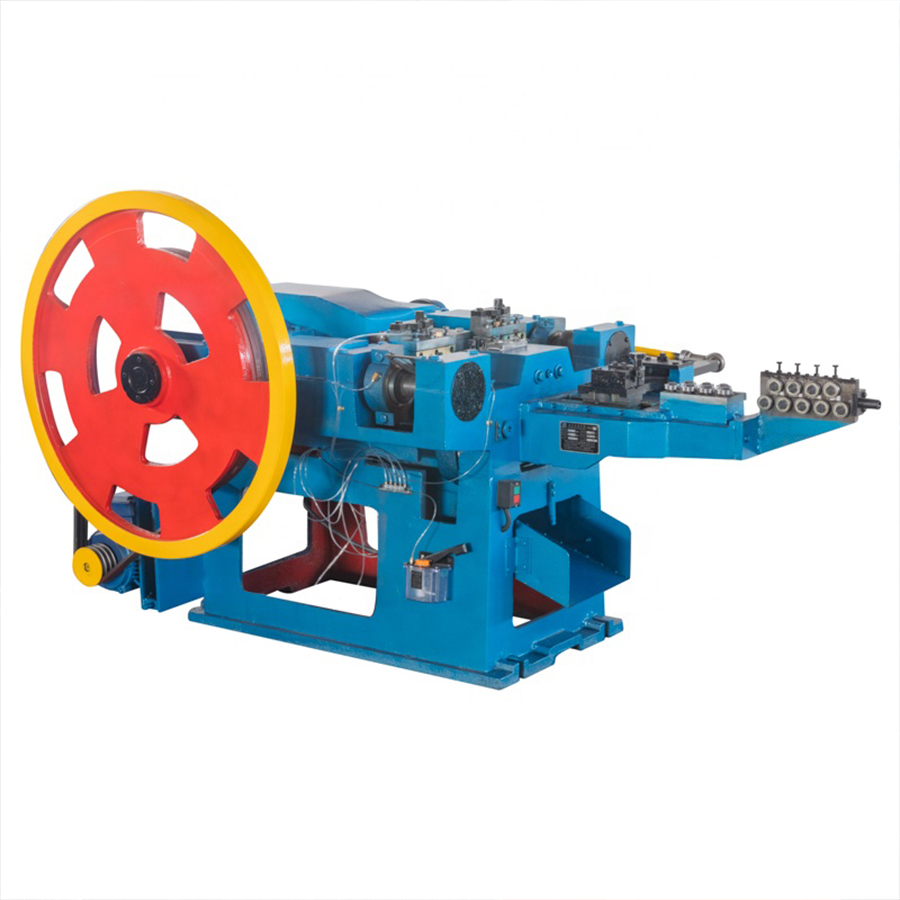

Automatic Control Common Nail Making Machine KYA-Z94

The KYA-Z94 Nail Making Machine is a compact, fully automatic solution for producing high-quality wire nails from 9mm to 330mm. Utilizing Taiwan nail-making technology, it offers low noise, low power consumption (as low as 4kW), and simple installation. Its plunger structure ensures high-speed production with minimal impact, ideal for coil nails, paper tape collated nails, and steel nails.

Produces nails from 9mm to 330mm with ±0.2mm length tolerance

Low running costs and affordable spare parts

Quick adjustments: 10 minutes for diameter, 5 minutes for length

High-speed production (90–450 pcs/min) with low noise

Compatible with welding machines and nail gun studs

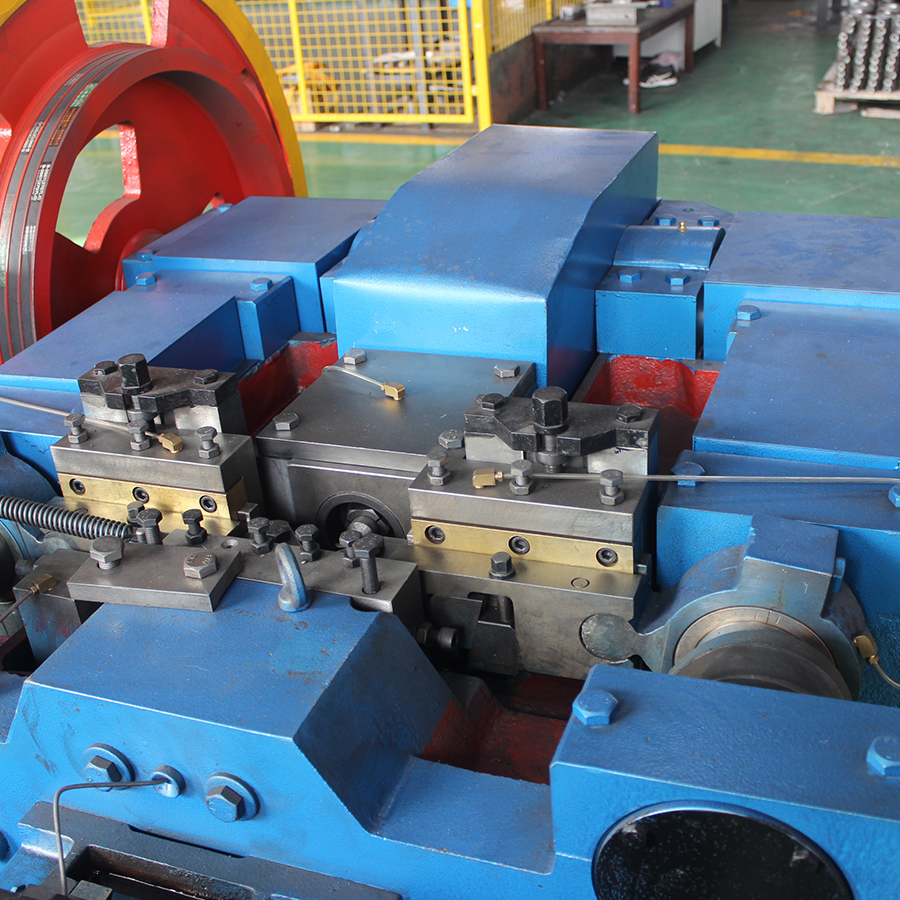

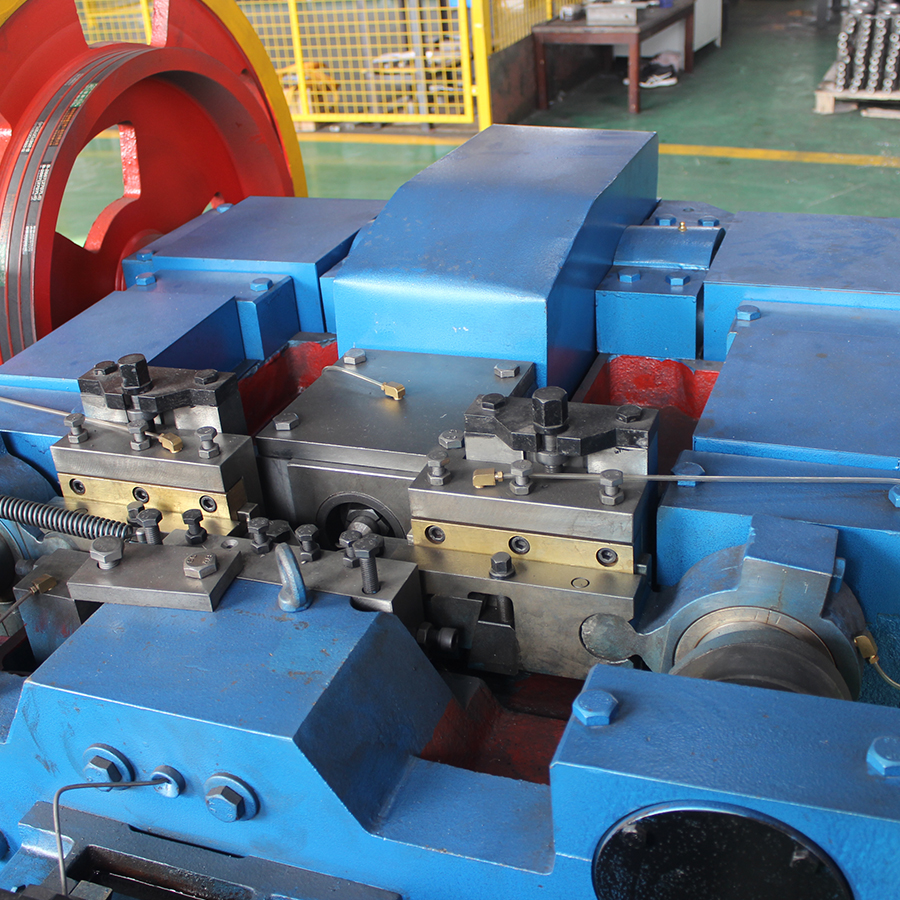

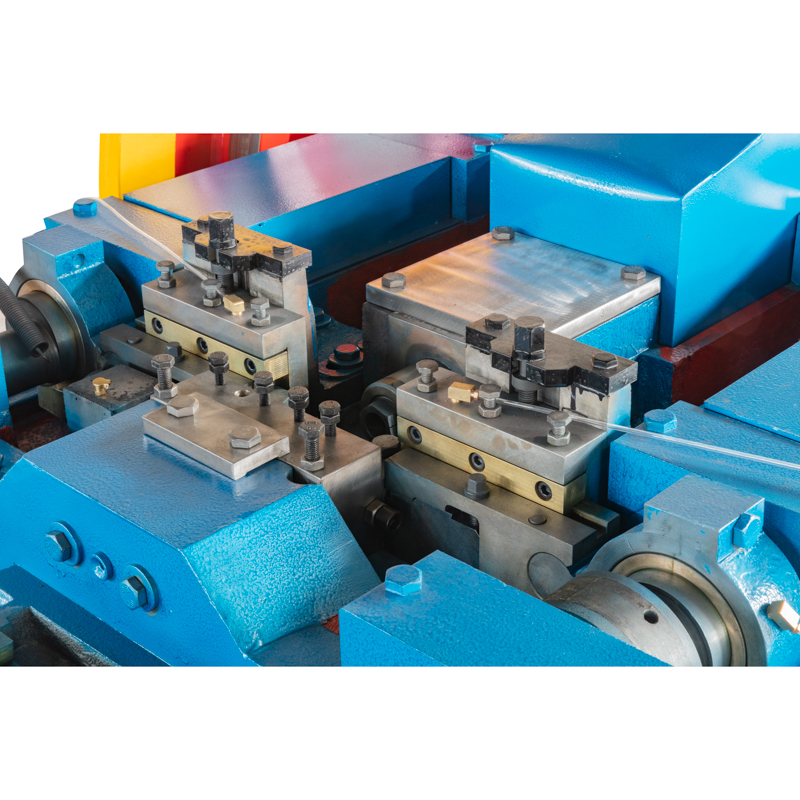

The KYA-Z94 Nail Making Machine uses a plunger structure driven by a 3-phase electric motor with auto oil pipe lubrication. It features a single punch bar, nail die, and nail cutter, producing one nail at a time with high precision.

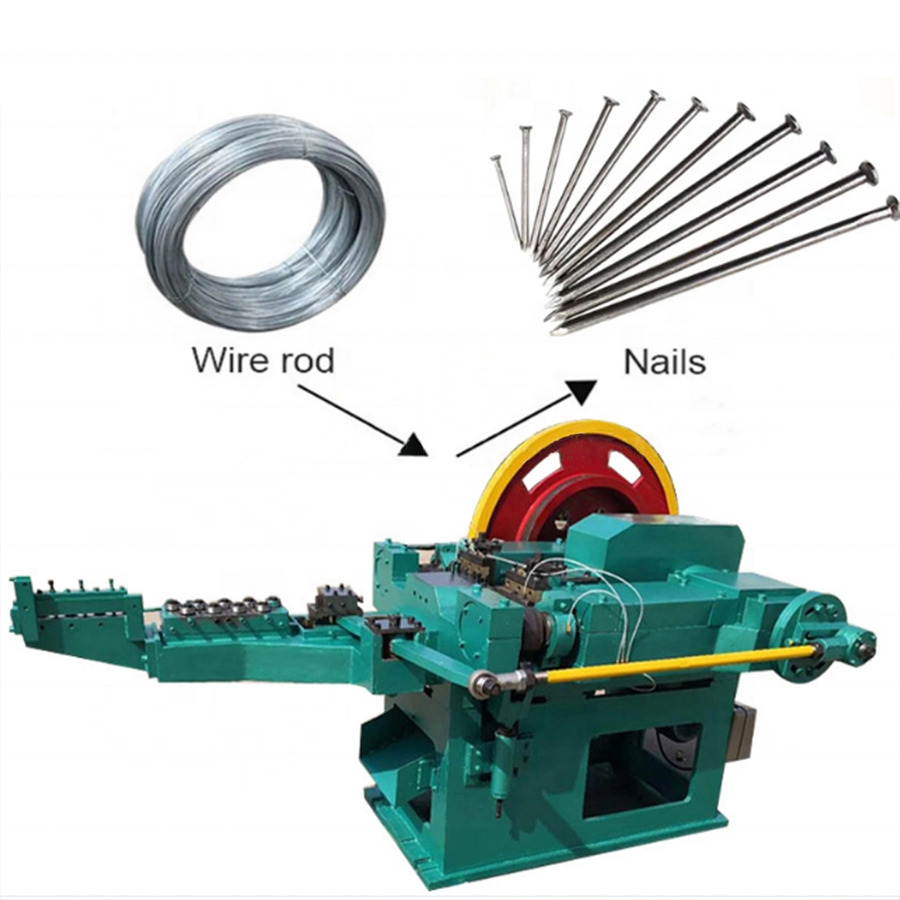

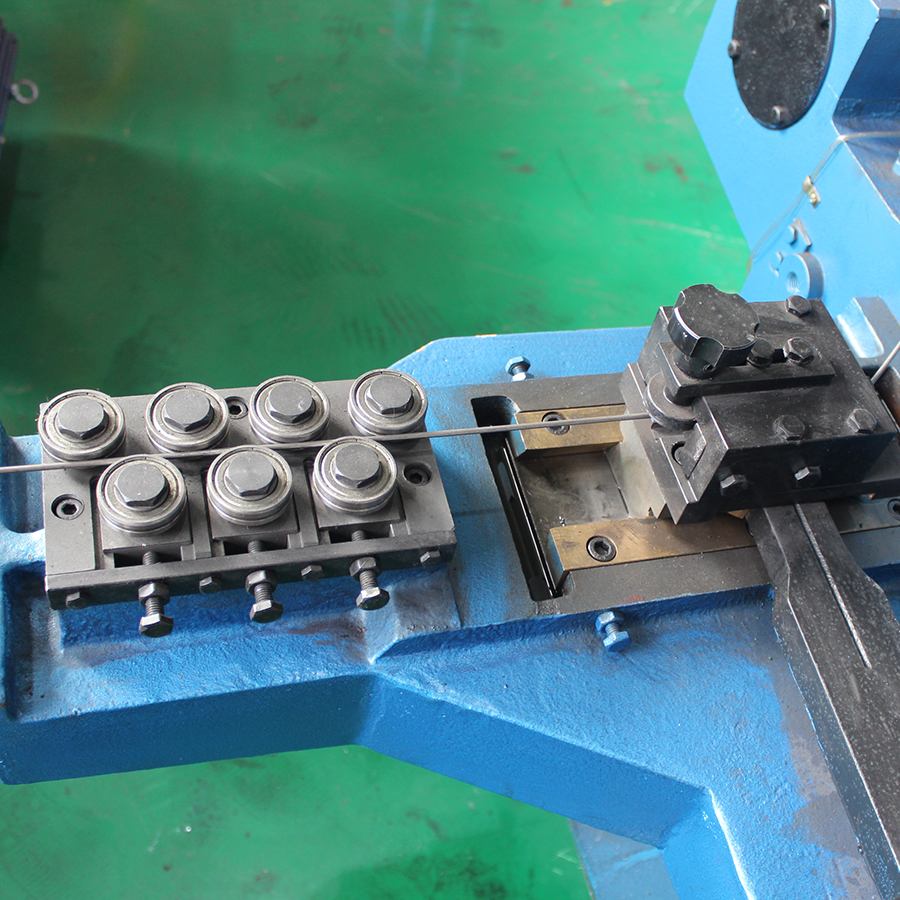

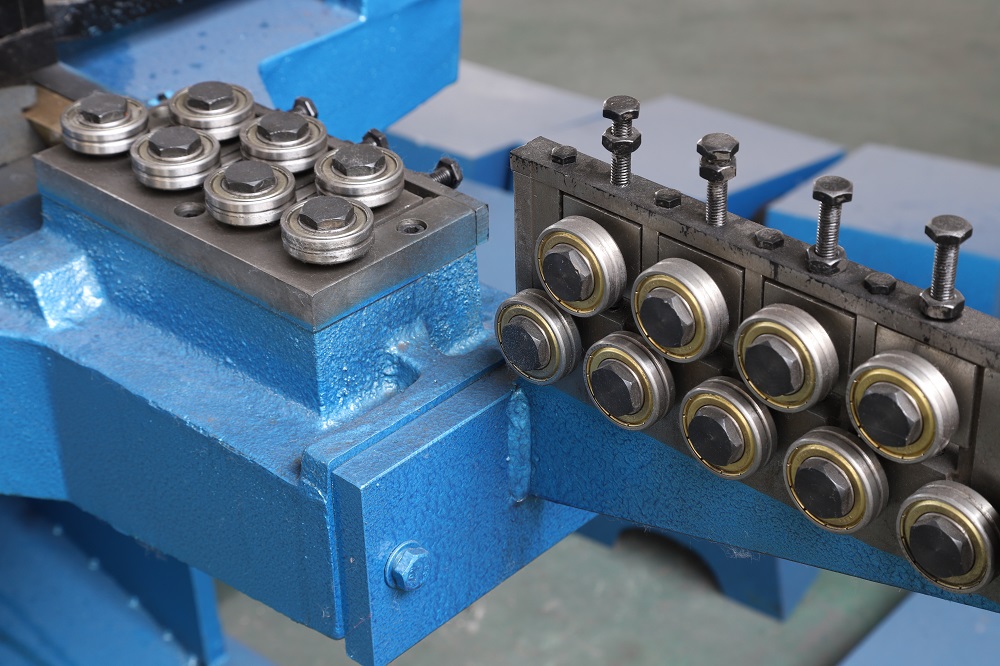

Wire Straightening: Wire coil is placed on a pay-off rack and fed into a straightening device.

Wire Feeding: The feeding box continuously grips and feeds the steel wire.

Nail Head Forming: The gripping mechanism clamps the wire, and the punch system forms the nail head.

Nail Tip Cutting: The cutting mechanism cuts the wire to form the nail point, with an emergency return option.

Final Step: The gripping die opens, the nail drops, and the cycle repeats.

![Wire Nail Making KYA-Z94 Wire Nail Making Process]()

![Steel Nail Making Machine KYA-Z94 Steel Nail Production]()

What types of nails can the KYA-Z94 produce?

The KYA-Z94 produces coil nails, paper tape collated nails, and steel nails, ranging from 9mm to 330mm in length.

How fast can the KYA-Z94 produce nails?

Depending on the model (Z94-1C to Z94-8C), it produces 60–450 nails per minute, with smaller nails achieving higher speeds.

How easy is it to adjust nail sizes on this machine?

Adjusting nail diameter takes 10 minutes with a mold change, and nail length adjustments take 5 minutes without any changes.

What are the power requirements for the KYA-Z94?

Power consumption ranges from 1.5 kW to 11 kW, depending on the model, with the smallest model (Z94-1C) using just 1.5 kW.

Is the KYA-Z94 suitable for high-speed nail production?

Yes, its plunger structure and cam mechanism ensure high-speed production, ideal for welding machines and nail gun studs.

What maintenance is required for the KYA-Z94?

The machine features auto oil pipe lubrication, reducing maintenance needs. Spare parts are affordable, ensuring low upkeep costs.

With over 20 years of expertise, KYA Fasteners is a trusted global supplier of industrial nail-making machines and fastening solutions. The KYA-Z94 Nail Making Machine is engineered for efficiency, precision, and cost-effectiveness in producing high-quality nails. For inquiries or custom configurations, Request a Quote today.

![KYA-Z94 Manufacturing KYA Fasteners Nail Making Machine Facility]()

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa