Overview

14 Gauge 1/2" Stainless Steel Loose Hog Rings (514DSSB)

Key Features of 14 Gauge Stainless Steel Hog Rings

304 stainless steel for corrosion resistance

High tensile strength (828 N/mm²)

Blunt tips for enhanced safety

1/2" open diameter, 1/4" closed diameter

2.0mm thickness for durability

Packaged 25 lbs per box, 80 boxes per skid

Request a Quote Product Specifications

Detailed Specifications for 14 Gauge Stainless Steel Hog Rings

| Specification | Details |

| Item | 14 Gauge Stainless Steel Loose Hog Rings (514DSSB) |

| Gauge | 14 Gauge |

| Fastener Type | D Rings |

| Material | 304 Stainless Steel |

| Finish | Stainless Steel |

| Point | Blunt |

| Open Diameter | 1/2" (12.7mm) |

| Closed Diameter | 1/4" (6.35mm) |

| Thickness | 2.0mm |

| Tensile Strength | 110-130 kpsi (828 N/mm²) |

| Packaging | 25 lbs/box, 80 boxes/skid (2000 lbs/skid) |

| Description | Part # | Box Weight | Boxes per Skid | Skid Weight |

| 15g Bright Loose Sharp (3/4") | 15DL | 25 lbs | 80 | 2000 lbs |

| 15g Stainless Loose Blunt (3/8") | 315DSSB | 25 lbs | 80 | 2000 lbs |

| 14g Galvanized Loose Blunt (3/8") | 314DGB | 25 lbs | 80 | 2000 lbs |

| 14g Stainless Loose Blunt (3/8") | 314DSSB | 25 lbs | 80 | 2000 lbs |

| 15g Stainless Loose Blunt (1/2") | 515DSSB | 25 lbs | 80 | 2000 lbs |

| 14g Galvanized Loose Blunt (1/2") | 514DGB | 25 lbs | 80 | 2000 lbs |

| 14g Stainless Loose Blunt (1/2") | 514DSSB | 25 lbs | 80 | 2000 lbs |

| 15g Stainless Loose Blunt (3/4") | 715DSSB | 25 lbs | 80 | 2000 lbs |

| 14g Galvanized Loose Blunt (3/4") | 714DGB | 25 lbs | 80 | 2000 lbs |

| 14g Stainless Loose Blunt (3/4") | 714DSSB | 25 lbs | 80 | 2000 lbs |

The 14 Gauge 1/2" Stainless Steel Loose Hog Rings (514DSSB) are optimized for upholstery, fencing, and cage assembly. Contact KYA Fasteners for bulk orders or custom specifications.

Request a Bulk Quote Finishing Options

Finishing Options for Hog Rings

Bright Finish

Bright finish hog rings lack coating and are prone to corrosion in humid or wet conditions. They are suitable for indoor applications where corrosion protection is not needed.

Electro-Galvanized (EG)

Electro-galvanized hog rings have a thin zinc layer for minimal corrosion protection, ideal for areas with light humidity, such as indoor upholstery.

Hot-Dip Galvanized (HDG)

Hot-dip galvanized hog rings feature a thicker zinc coating for outdoor use in rain or snow, but are less suitable for coastal areas due to salt-accelerated corrosion.

Stainless Steel (SS)

304 stainless steel hog rings offer the best corrosion resistance, ideal for both indoor and outdoor applications, including marine environments, without losing strength.

Applications

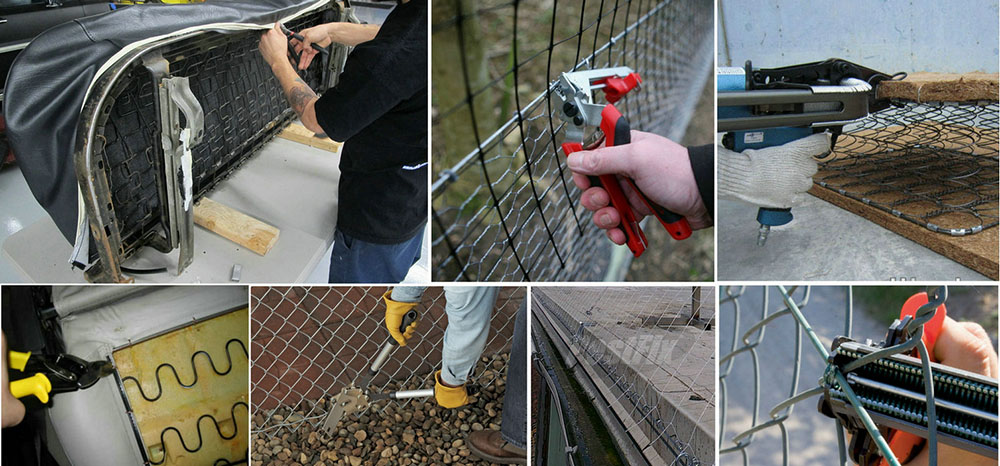

Applications for 14 Gauge Stainless Steel Hog Rings

The 14 Gauge 1/2" Stainless Steel Loose Hog Rings are ideal for secure fastening in various applications, with custom specifications available on request.

Wire fencing (chain link, welded wire mesh, chicken wire, plastic mesh)

Wire cage assembly (lobster/crab pots, rabbit cages, dog kennels, animal cages)

Upholstery (automotive and domestic)

Gardening (bird netting, trellises)

Netting and silt fence installation

Bungee cord securing

Bag closure

Explore Related Hog Rings Frequently Asked Questions

FAQs About 14 Gauge Stainless Steel Hog Rings

What are these hog rings used for?

They are used for wire fencing, cage assembly, upholstery, gardening, netting, bungee cord securing, and bag closure.

Why choose stainless steel hog rings?

304 stainless steel ensures superior corrosion resistance, ideal for outdoor and marine environments, with no strength loss.

What is the benefit of blunt tips?

Blunt tips enhance safety by reducing the risk of injury during handling and installation.

What are the dimensions of the 514DSSB hog rings?

They have a 1/2" (12.7mm) open diameter, 1/4" (6.35mm) closed diameter, and 2.0mm thickness.

How are these hog rings packaged?

They are packaged 25 lbs per box, with 80 boxes per skid, totaling 2000 lbs per skid.

Can custom specifications be ordered?

Yes, KYA Fasteners offers custom specifications for hog rings upon request.

Ask a Question About KYA Fasteners

Why Choose KYA Fasteners for Hog Rings?

With over 20 years of expertise, KYA Fasteners is a trusted leader in industrial fasteners, delivering high-quality 14 Gauge 1/2" Stainless Steel Loose Hog Rings. Our SGS-certified production ensures precision and durability, serving clients in over 50 countries. We ship from Qingdao port within 20-30 days, offering customized solutions for fastening needs.

Global Reach: Exporting to 50+ countries with reliable hog rings

Premium Quality: Durable, corrosion-resistant fasteners for professional use

Fast Delivery: Ships worldwide in 20-30 days from Qingdao port

Custom Solutions: Tailored specifications for specific projects

Enhance your projects with 14 Gauge Stainless Steel Hog Rings. Request a free quote today to experience KYA's quality and service.

Contact KYA Fasteners English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa