Product Video

Watch the Stitching Wire in Action

Overview

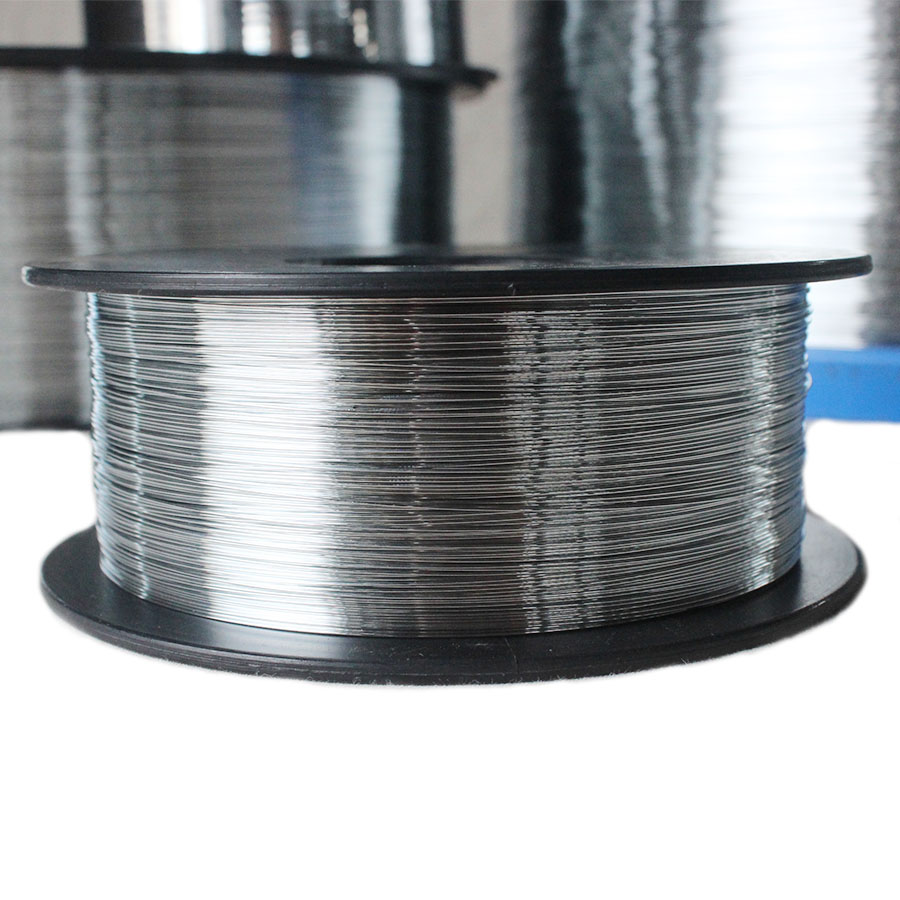

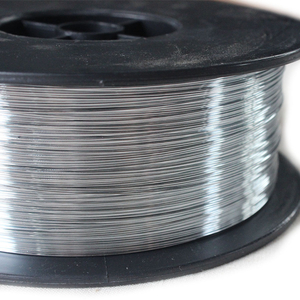

26 Gauge Galvanized Box Stitching Wire

![KYA Fasteners Stitching Wire 26 Gauge Galvanized Box Stitching Wire for carton stitching]()

KYA Fasteners' 26 Gauge Galvanized Box Stitching Wire is engineered for high-performance stitching in cardboard packaging, cartons, and booklets. Made from low to medium carbon steel with a zinc-galvanized or tin coating, this wire ensures superior rust resistance and reliable operation. Available in diameters from 0.40mm to 1.00mm, it supports 21 to 30 gauge sizes for round wire and various flat wire dimensions. Offered on spools from 2kg to 100kg, it suits side, saddle, and corner stitching in high-speed applications. With optimized surface structure and precise manufacturing, this wire minimizes downtime and enhances productivity for industrial stitching needs.

Key Features of Galvanized Stitching Wire

Zinc or tin coating for excellent rust resistance

Diameters from 0.40mm to 1.00mm (21-30 gauge)

Available in round and flat wire configurations

Spool sizes: 2kg, 3.5kg, 10kg, 15kg, 100kg

Optimized surface for low friction and reliable feeding

Clean, non-cross-wound wire to minimize jams

Request a Quote Product Specifications

Detailed Specifications for Stitching Wire

Round Stitching Wire

| Wire Gauge | German Wire Gauge (mm) | m/kg | ASWG (mm) | m/kg | ft/lb | BWG (mm) | m/kg | ft/lb |

| 21 | 0.80 | 253 | 0.81 | 247 | 368 | 0.81 | 247 | 368 |

| 22 | 0.75 | 288 | 0.73 | 304 | 452 | 0.71 | 322 | 479 |

| 23 | 0.65 | 331 | 0.65 | 384 | 571 | 0.63 | 409 | 609 |

| 24 | 0.60 | 451 | 0.58 | 482 | 717 | 0.56 | 517 | 769 |

| 25 | 0.55 | 536 | 0.52 | 600 | 893 | 0.51 | 624 | 929 |

| 26 | 0.50 | 649 | 0.46 | 767 | 1141 | 0.46 | 767 | 1141 |

| 27 | 0.45 | 801 | 0.44 | 838 | 1247 | 0.41 | 965 | 1436 |

| 28 | 0.40 | 1014 | 0.41 | 965 | 1436 | 0.36 | 1252 | 1863 |

| 29 | 0.37 | 1185 | 0.38 | 1123 | 1671 | 0.33 | 1489 | 2216 |

| 30 | 0.35 | 1324 | 0.36 | 1252 | 1863 | 0.30 | 1802 | 2682 |

Flat Stitching Wire

| Wire Gauge | Size (inches) | Size (mm) | Feet per Pound | Recommended Work Thickness |

| 18 x 20 | 0.047 x 0.035 | 1.20 x 0.90 | 221 | 5/8" - 2" |

| 19 x 21.5 | 0.041 x 0.030 | 1.05 x 0.75 | 283 | 1/2" - 1" |

| 19.5 x 21 | 0.037 x 0.031 | 0.95 x 0.80 | 283 | 1/2" - 1" |

| 20 x 24 | 0.035 x 0.023 | 0.90 x 0.60 | 408 | Up to 3/16" |

| 20 x 25 | 0.035 x 0.021 | 0.90 x 0.55 | 455 | 1/8" - 5/8" |

| 21 x 25 | 0.031 x 0.021 | 0.80 x 0.55 | 559 | 1/16" - 1/2" |

General Specifications

| Specification | Details |

| Material | Low to Medium Carbon Steel |

| Coating | Zinc Galvanized or Tin |

| Diameter Range | 0.40mm - 1.00mm (21-30 Gauge) |

| Packing | 2kg, 3.5kg, 10kg, 15kg, 100kg spools |

| Customization | Available per customer specifications |

![Stitching Wire for Booklet Making Galvanized stitching wire for booklet making]()

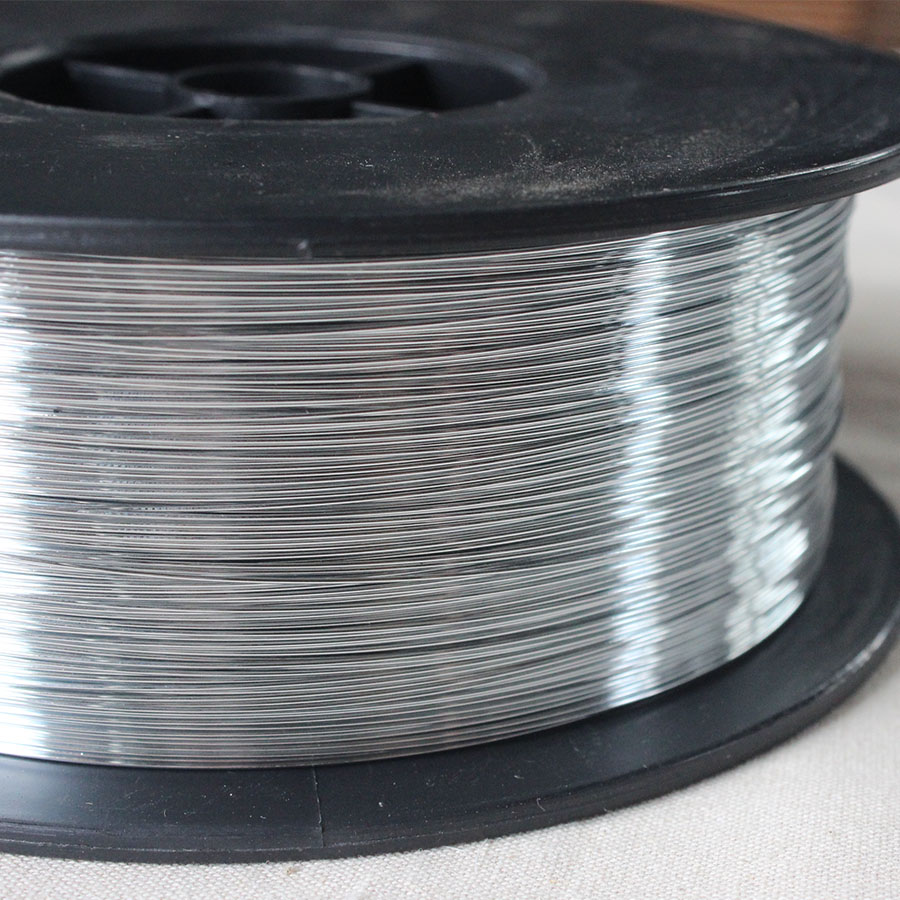

The 26 Gauge Galvanized Box Stitching Wire is optimized for high-speed stitching applications. Contact KYA Fasteners for bulk orders or custom specifications.

Request a Bulk Quote Features

Key Features of Stitching Wire

Strong zinc or tin coating for corrosion resistance

Optimized surface structure for low friction

Consistent mechanical properties for trouble-free processing

Non-cross-wound wire to prevent jams and downtime

Precise manufacturing tolerances for excellent penetration

Environmentally friendly coating for sustainability

Applications

Applications for Stitching Wire

The 26 Gauge Galvanized Box Stitching Wire is ideal for various stitching applications in packaging and printing.

Explore Related Stitching Wire Path of Wire

Path of Wire for Optimal Performance

A clean wire path from spool to stitching head is critical for optimal performance. Avoid damage to the zinc or tin coating by ensuring the wire avoids unprotected steel brackets, worn wire guides, spring tubes, or dirty felt pads. Regular inspection and replacement of wire guides, springs, and felt pads prevent flaking, jamming, and costly downtime in stitching operations.

Frequently Asked Questions

FAQs About Galvanized Stitching Wire

What is the stitching wire used for?

It is used for stitching cardboard packaging boxes, cartons, booklets, and in side, saddle, corner, and inline press applications.

What materials and coatings are used?

Made from low to medium carbon steel with zinc-galvanized or tin coating for rust resistance.

What are the available spool sizes?

Available in 2kg, 3.5kg, 10kg, 15kg, and 100kg spools.

What wire gauges are offered?

Round wire: 21-30 gauge (0.40mm-1.00mm); flat wire: sizes like 18 x 20 to 21 x 25.

Why is the wire path important?

A clean wire path prevents coating damage, jamming, and downtime, ensuring smooth stitching operations.

Can the wire be customized?

Yes, technical specifications can be customized per customer request.

Ask a Question About KYA Fasteners

Why Choose KYA Fasteners for Stitching Wire?

With over 20 years of expertise, KYA Fasteners is a trusted leader in industrial fasteners, delivering high-quality 26 Gauge Galvanized Box Stitching Wire. Our SGS-certified production ensures precision and durability, serving clients in over 50 countries. We ship from Qingdao port within 20-30 days, offering customized solutions for stitching needs.

Global Reach: Exporting to 50+ countries with reliable stitching wire

Premium Quality: Rust-resistant, high-performance wire for industrial use

Fast Delivery: Ships worldwide in 20-30 days from Qingdao port

Custom Solutions: Tailored wire specifications for specific applications

Enhance your stitching operations with Galvanized Box Stitching Wire. Request a free quote today to experience KYA's quality and service.

Contact KYA Fasteners English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa