Introduction

This guide will explain some of the most common (and some specialized) nail types DIYers might run into. From light-duty to heavy-duty and big to small, keep reading to learn more about 25 nail types and the applications for each type.

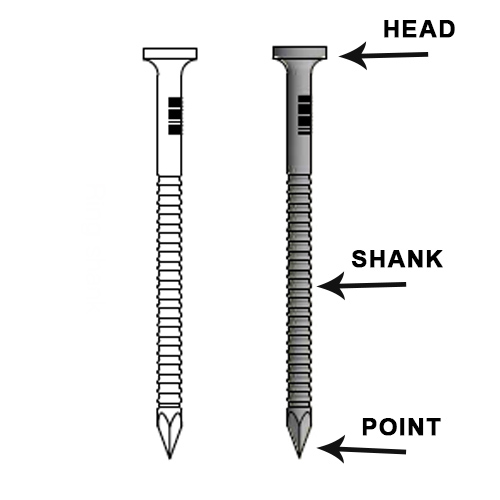

Parts of a Nail

![the parts of nails the parts of nails]()

In most cases, there are three main parts of a nail. These three parts include the head, the shank, and the point. Each of these parts serves a purpose.

The head of a nail is the flat surface on the rear of the nail that the user strikes with a hammer. The head serves two purposes: It acts as a striking surface for driving the nail but also acts as more surface area for pinning the material in place. There are several types of nail heads, including flat, countersink, checkered, and more.

The shank is the long, thin section of the nail that stretches from the head to the point. This section is usually cylindrical, but many nails have specialized shanks that provide them with specific capabilities.

The point is the section of the nail that penetrates the wood. On the surface, points look conical, but most actually consist of flat sections. This helps the nail act as a wedge, splitting the fibers apart as the user drives it. Conversely, some nails have blunted tips, and they punch the fibers forward as the user drives the nail rather than wedging, and this makes blunted tips less likely to split wood.

Nail Size Chart

The D in nail sizes indicates “penny,” and they’re pronounced as such: 10D is pronounced “ten-penny.” Originally, the term indicated how many pennies a carpenter would have to pay for 100 nails of a specific length.

The following table is the length of each number.

| Penny Size | Length | Steel Wire Gauge |

| in. | mm | in. |

| 2d | 1 | 25.4 |

| 3d | 1-1/4 | 31.7 |

| 4d | 1-1/2 | 38.1 |

| 5d | 1-3/4 | 44.4 |

| 6d | 2 | 50.8 |

| 7d | 2-1/4 | 57.1 |

| 8d | 2-1/2 | 63.5 |

| 9d | 2-3/4 | 69.8 |

| 10d | 3 | 76.2 |

| 12d | 3-1/4 | 82.5 |

| 16d | 3-1/2 | 88.9 |

| 20d | 4 | 101.6 |

| 30d | 4-1/2 | 114.3 |

| 40d | 5 | 127.0 |

| 50d | 5-1/2 | 139.7 |

| 60d | 6 | 152.4 |

| 70d | 7 | 177.8 |

The penny system is primarily used for nails for wood framing, such as sinkers, common nails, and box nails. And despite the clear and reasonable preference for nail guns, most framing carpenters often carry three nail sizes, and they are 8D, 10D, and 16D.

The typical use for an 8D nail is attaching a wall plate to the subfloor. Since they’re cheaper, they’re also commonly used for attaching chalk lines to sheet goods or to act as hinges when lifting framed wall assemblies. They can also attach furring strips, sheathing, and other thinner materials.

Ten-penny (10D) nails are typically used for building header assemblies and framing walls. Their 3-inch length means they can punch through two 2x6s, 2x8s, or 2x10s with a ½-inch piece of plywood between them (a header sandwich) without poking through the other side. They may also be used for non-loadbearing walls.

The 16D nail is the workhorse of the framing crew. These nails are long and strong, and they’re used for actual wall assemblies. The carpenter nails through the face of the top and bottom plates and into the ends of the individual wall studs, pinning them in place as a wall assembly. These nails provide enough holding power while also allowing the walls to rack and adjust a bit over time without breaking.

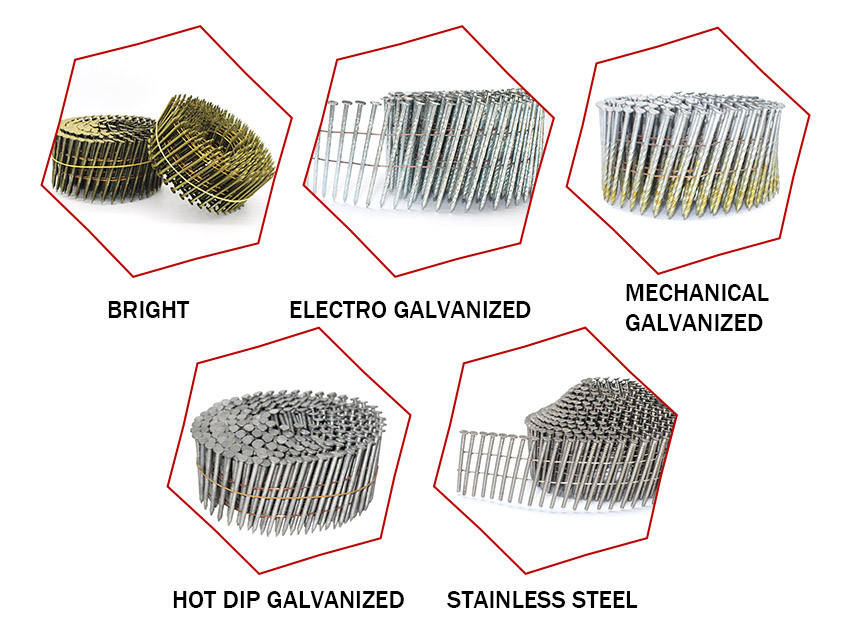

Nail Materials and Finishes

![15 degree coil nails 15 degree coil nails]()

As far as materials go, most kinds of nails are steel. However, there are also nails in materials such as stainless steel, copper, iron, aluminum, or bronze. Stainless steel nails are useful since they don’t react with materials like cedar or redwood. Copper nails are useful when installing copper flashing or copper ceiling tiles.

Most of the time, the finish either affects the way the nail sinks into the wood or how corrosion-resistant the nail is. Common nail finishes include:

Bright: Unfinished, raw metal.

Galvanized: Dipped in a corrosion-resistant coating.

Black phosphate: A thin layer of protection that promotes paint adhesion.

Zinc-plated: A thin coating of zinc that works best indoors, and it typically looks silver or gold in color but adds corrosion resistance.

General Nails

One walk down the fasteners aisle at a big box home improvement store will prove that nail varieties abound. However, some nails are more common than others, and this guide will break down some of the different types of nails.

![steel nails steel nails]()

As the name suggests, common nails are your everyday nails. They are generally used for rough construction work, and can be driven into hard materials. They typically have a bright finish, which means they won’t last long in outdoor applications.

Best For: Framing and general construction work that isn’t exposed to weather.

2. Box Nails

![BOX NAILS steel nails-9]()

These look like common nails, but they are thinner. This means they are less likely to cause splits in the wood but they also have less holding power. So, if structural strength is critical, avoid box nails.

Best For: General construction, but they don’t have the strength of a common nail.

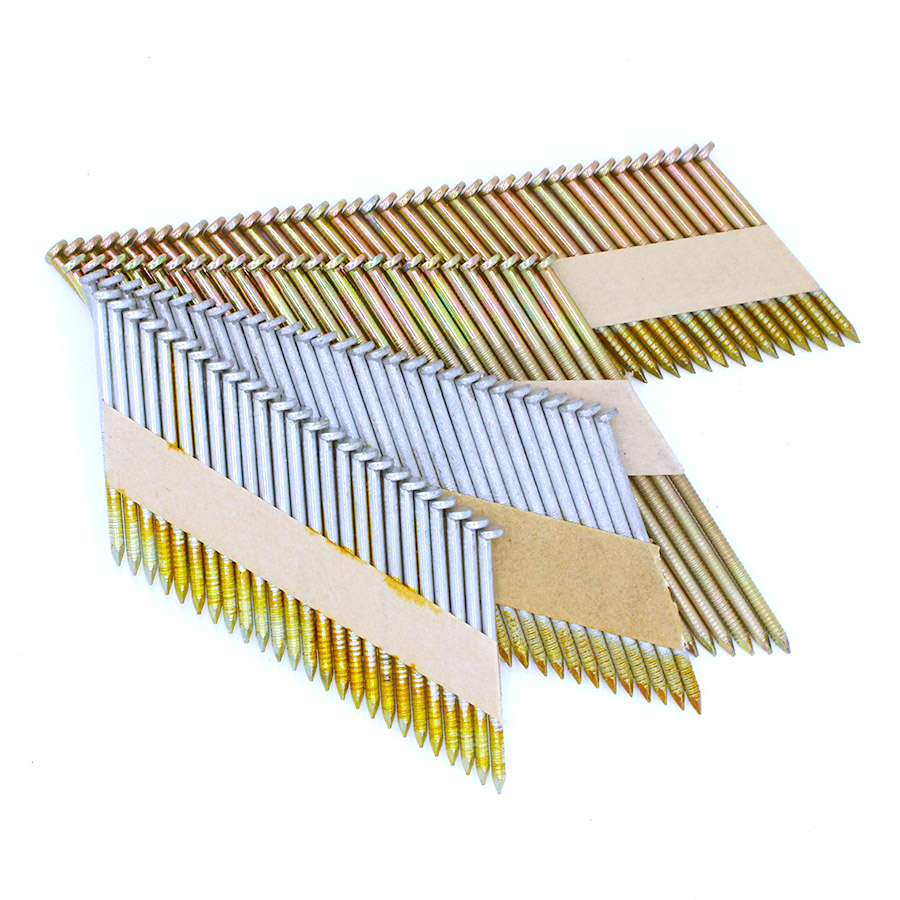

![framing nails framing nails]()

Framing nails are essentially the same as common nails, and they are the general construction nails many are used to seeing. They have thick shanks, wide heads, and provide a lot of holding power and strength. They come in a bright finish for indoor projects and galvanized for outdoor projects. They’re also available in many sizes.

Best For: Framing and general construction work.

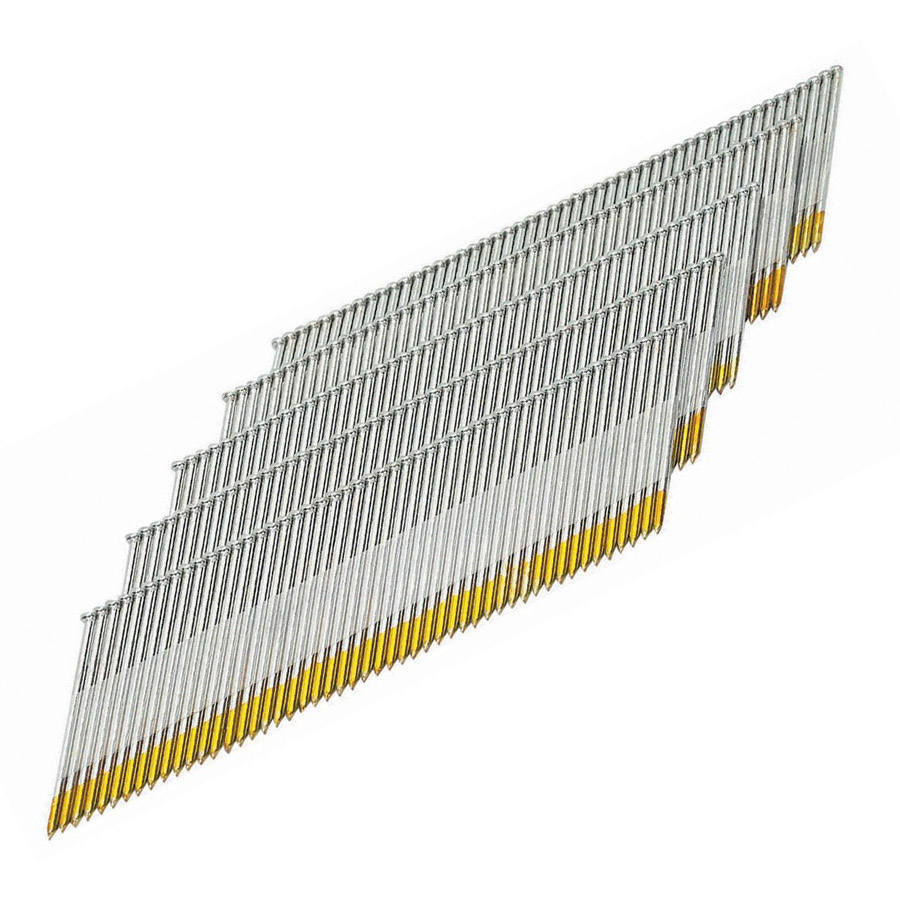

![finish nails 15 ga angled finish nails]()

Finishing nails are used for finish work. Their barrel-shaped heads are small and can be driven below the surface of the wood using a nail set (a technique called countersinking). Finishing nails are useful for installing trim, crafting furniture, and building other projects where you want to hide the head of the fastener.

Best For: Trim, moldings, and other finish work.

![T BRAD NAILS T BRAD NAILS]()

Brads are used as finishing nails but are proportionately smaller in diameter, with smaller heads. Brads are used in building frames, attaching plywood paneling, some moldings, and in cabinet work. Their slightly thinner diameter and smaller heads make them less likely to split wood, and easier to hide.

Best For: Building frames, attaching paneling, moldings, and some cabinet work.

6. Pin Nails

![pin nails pin nails]()

Pin nails are small wire nails without heads. They’re extremely thin, can only be fired from a pin nailer, and don’t offer much holding strength. However, their thin design and lack of a head make them almost invisible once fired and they hardly ever split wood. This makes pin nails a popular choice for picture framing, attaching delicate moldings such as thin beads or rope patterns, as well as fastening thin cornice moldings to cabinets.

Best For: Building picture frame, attaching delicate moldings, and installing cornice molding to cabinets.

![concrete nails concrete nails]()

Concrete nails are made of carbon steel for ensuring high hardness, toughness, and long durability; Smooth surface with thick galvanized coating, no flash, and anti-corrosion. Less jamming; Gather the concrete nails with glue to prevent loosening & breaking. Packed with a plastic box for neat placing.

Best For: Works great to concrete nailing, furring strips, truss building, construction framing, decking, and more.

![Joist hanger nails Joist hanger nails]()

Hanger nails are stubby galvanized nails used to attach joist hangers to ledgers. They don’t have to be long because they simply pinch the joist hanger (which is under 1/8-inch thick) to the ledger, and then the joist to the joist hanger. They may also be used to attach stair stringers, hurricane ties, strapping, and other galvanized brackets. Joist hanger nails provide much more holding and sheer strength than nailing into the end of the joist.

Best For: Attaching joist hangers, stringer hangers, hurricane ties, and strapping on outdoor decks.

![roofing nails roofing coil nails]()

Roofing nails have disproportionately large, round heads and heavier shanks than many other nails. Designed to hold composite and asphalt roofing materials in place without tearing, roofing nails are heavily galvanized to resist rust.

Best For: Fastening shingle tabs to roof decks.

![coil siding nails coil siding nails]()

There are a couple of types of siding nails, including the annular ring shank nail described above, and those with spiral shanks. These nails have thin shanks (with a ring or spiral) and wide heads. Siding nails used to nail through the face of clapboard will have exposed heads, so it’s best to use galvanized siding nails in these cases. The exception would be if the clapboard is cedar, which would require stainless steel nails.

Best For: Hanging siding and clapboard.

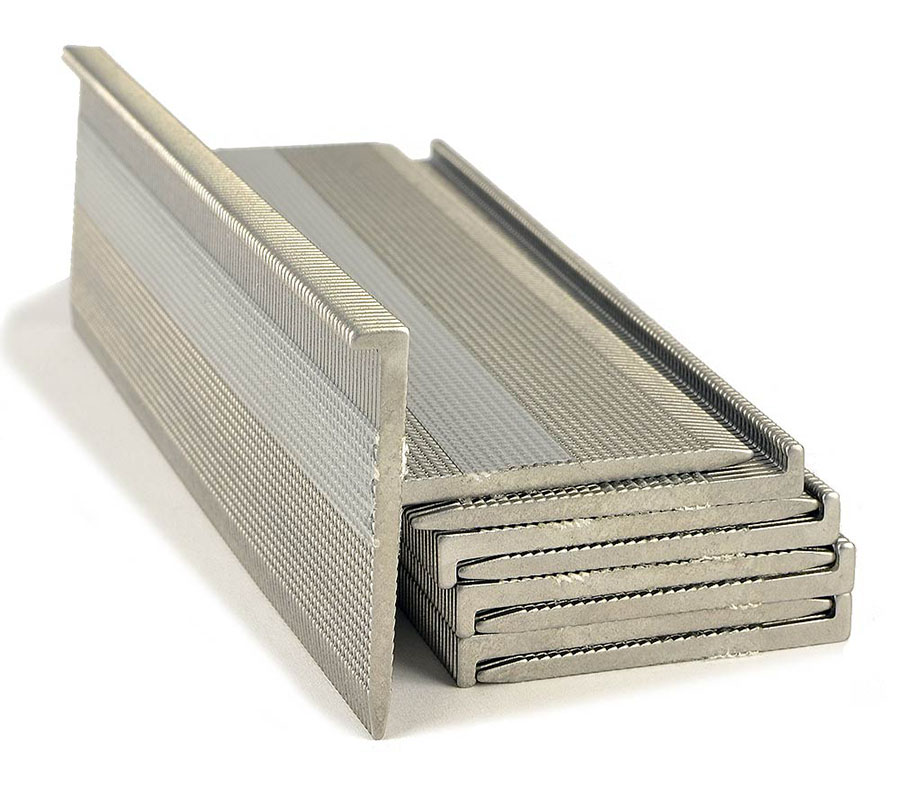

Cleat nails are commonly used fasteners in hardwood flooring projects. Available in 16 Gauge L Shaped and 16 Gauge T Shaped cleats,For installation of 1/2 in. to 3/4 in. solid wood flooring. Cupped point helps prevent splits in the wood. Wide-head wedge-shaped design for a tight floor.

Best For: Angle and face nailing applications without damage to the flooring.

![FLOORING CLEAT NAILS FLOORING CLEAT NAILS]()

![screw nails collated drywall screws]()

Collated screws mean increased productivity. Like their nail and staple counterparts, Collated screws offer professional installers a number of benefits, not the least of which is an overall increase in job productivity. This is due in part to the fact that collated systems reduce the amount of time spent loading and installing loose fasteners, eliminating the need for feeding one fastener at a time.

Best For: Drywall installation, building furniture, decks, steps, and frames.

Tips for Using Nails

The following are some helpful tips to consider when fastening with nails:

When driving small nails, avoid hitting fingers with a hammer by punching the nail through a small scrap of cardboard, holding the nail in place with the cardboard, and then driving it in with a hammer.

Pointed nail tips act like a wedge and split wood. Consider blunting the end of a nail by turning it over and tapping the point with a hammer. The blunted tip will punch the wood fibers through the board rather than wedging them apart.

When toe-nailing (a nailing technique used to drive nails at an angle), start the nail at a 90-degree angle to the board. Once the tip of the nail is about ⅛-inch into the board, adjust the nail to a 45 degree angle to the board and continue to drive it with the hammer.

Certain wood species, such as cedar or redwood, will react with bright nails, even in interior applications. Stainless steel, hot-dipped galvanized, or aluminum nails are better in these instances.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa