FAQs About T50 Brad Nailer

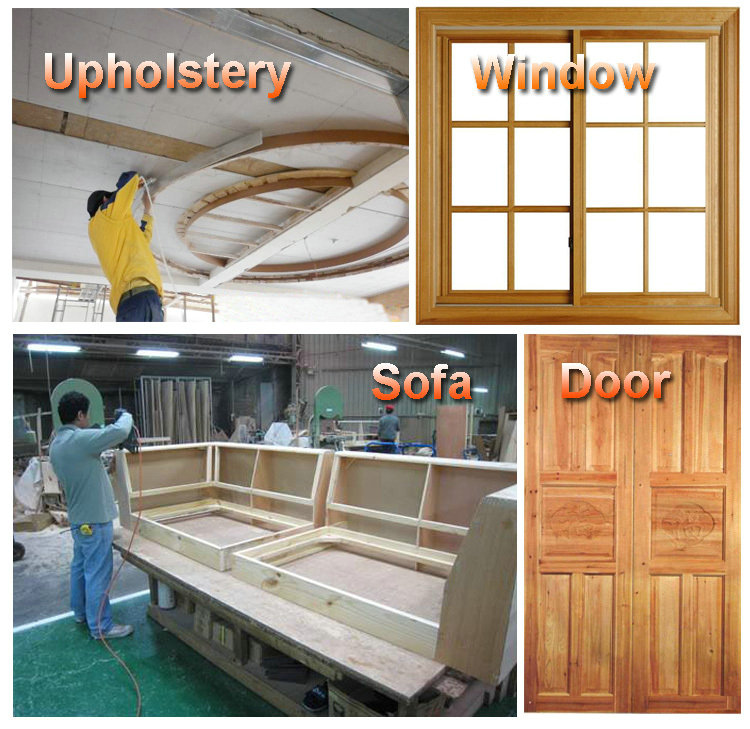

What is the T50 Brad Nailer used for?

It’s used for decorative trim, picture frame assembly, interior/exterior trim, cabinetry, upholstery, crafts, baseboards, crown molding, and staircases.

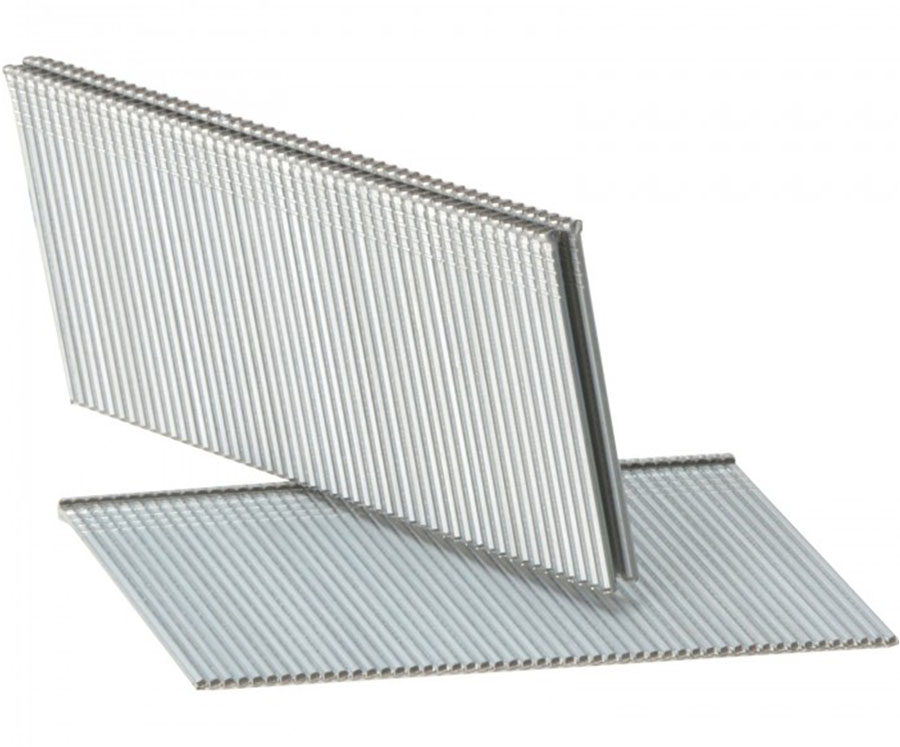

What nails are compatible with the T50?

It drives 16-gauge T brad nails from 13/16” to 2” (20mm to 50mm).

What is the operating pressure for the T50?

The T50 operates at 60-100 psi (4-7 bar) for optimal performance.

How does the tool-free depth adjustment work?

It allows precise control for flush or countersunk nail driving in various materials without tools.

What is the nail capacity of the T50?

It holds up to 100 nails per load, ideal for extended work sessions.

Can I request a demo or sample of the T50?

Yes, contact KYA Fasteners to arrange a demo or inquire about availability.

Ask a Question Why Choose KYA Fasteners for T50 Brad Nailer?

With over 20 years of expertise, KYA Fasteners is a trusted leader in industrial fastening tools, delivering the high-quality 16 Gauge Pneumatic 2-Inch Brad Nailer T50. Our SGS-certified production ensures precision and durability, serving clients in over 50 countries. We ship from Qingdao port within 20-30 days, offering customized solutions for finish and trim needs.

Global Reach: Exporting to 50+ countries with reliable brad nailers

Premium Quality: Durable tools for professional use

Fast Delivery: Ships worldwide in 20-30 days from Qingdao port

Custom Solutions: Tailored tools and accessories for specific projects

Enhance your finish work with the T50 Brad Nailer. Request a free quote today to experience KYA's quality and service.

Contact KYA Fasteners English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa