Pneumatic 18 Gauge 1/4" Narrow Crown Stapler 9040 (1.80kg, 110 Staples)

![16–40mm Staples 9040 18 Gauge Narrow Crown Stapler - KYA Fasteners]()

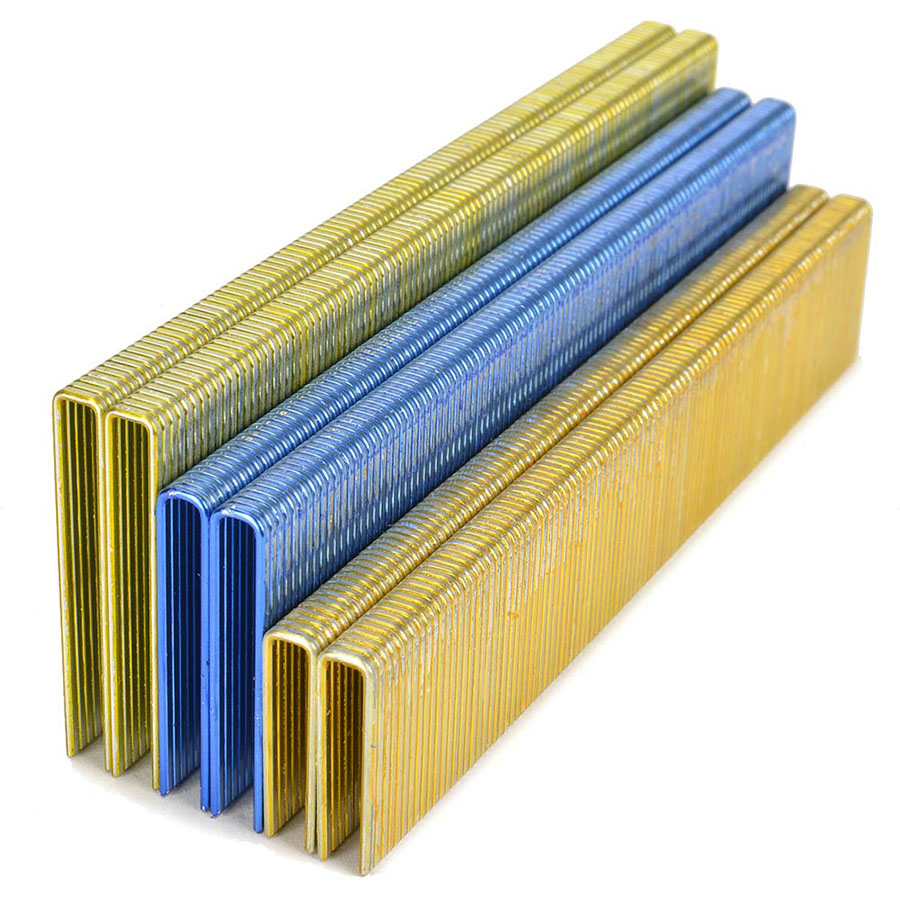

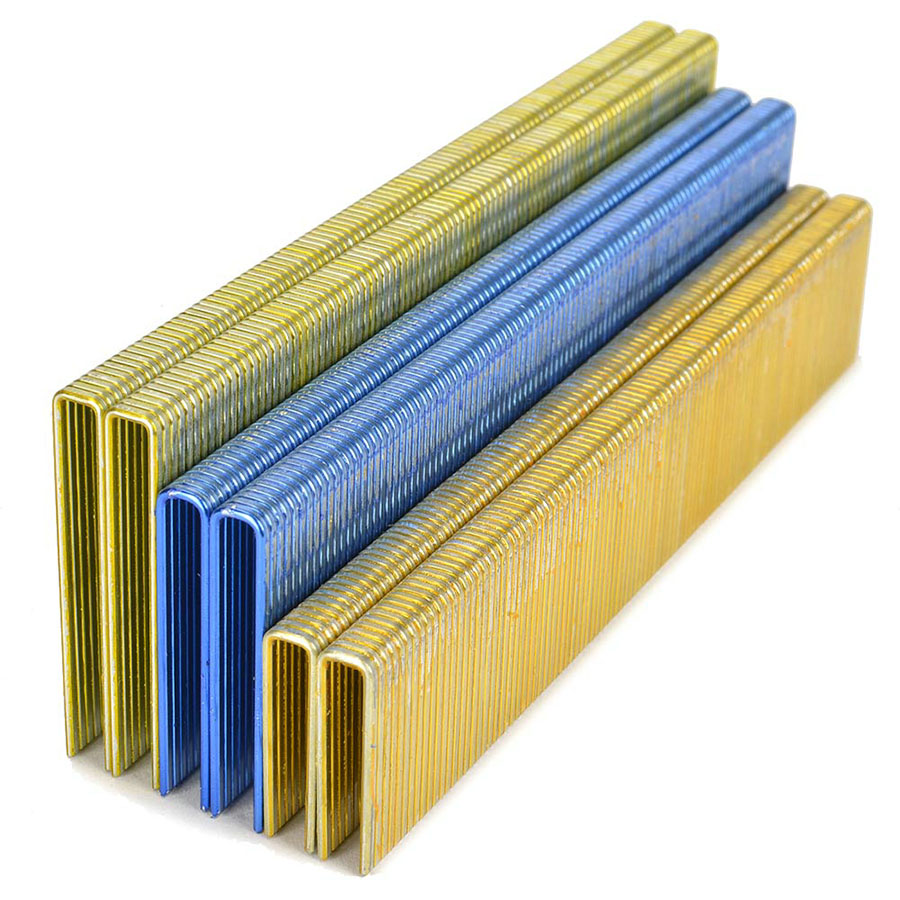

KYA Fasteners, a 20+ year factory, manufactures the 9040 pneumatic 18 gauge 1/4" narrow crown stapler for trim, cabinets, upholstery. Weighs 1.80kg, 110 staple capacity, 60–100 PSI. 360° exhaust, tool-less depth & jam clear, aluminum body. Drives 16–40mm high carbon steel staples. Exported to USA, Germany, Australia, Canada and 50+ countries.

![16–40mm 18 Gauge 1/4\Staples]()

![Cabinet Backing 9040 in Trim]()

Why Choose KYA 9040 Narrow Crown Stapler?

Factory direct – 20+ years experience

1.80kg lightweight – easy operation

Drives 16–40mm 18GA staples

110 staple capacity – high efficiency

Global shipping: USA, EU, AU, CA in 20–30 days

Request a Quote

Product Specifications

9040 Stapler Specs

| Model | Weight | Capacity | Staple Length | Crown | Pressure |

| 9040 | 1.80kg | 110 | 16–40mm | 1/4" (5.7mm) | 60–100 PSI |

225×78×264mm, 18GA high carbon steel, 1.25×1.05mm shank, 360° exhaust.

Request a Quote Features

9040 Stapler Features

Lightweight 1.80kg body — easy one-hand operation

Tool-less depth adjustment — precise flush or countersink

360° adjustable exhaust — clean workspace

Die-cast aluminum housing — durable & lightweight

Rubber comfort grip — non-slip, reduces fatigue

Long narrow nose — excellent visibility

Applications

Where Is 9040 Stapler Used?

Interior trim – crown molding, baseboards

Cabinet backing – drawer assembly

Upholstery – spring attachment

Insulation sheathing – foam board

Craft & hobby – picture frames

Explore All Staplers Frequently Asked Questions

9040 Stapler FAQ

What staples fit 9040 stapler?

18GA 1/4" crown: 16–40mm, 1.25×1.05mm shank, high carbon steel.

360° exhaust benefit?

Adjustable airflow — keeps dust away from user.

Tool-less depth?

Easy dial — flush or countersink control.

Best for trim work?

Yes — narrow nose for tight corners, 110 staple load.

Air pressure range?

60–100 PSI (4–7 bar) — standard compressor.

Ask a Question About KYA Fasteners

KYA Fasteners – 9040 Stapler Supplier

KYA Fasteners has manufactured 9040 18 gauge staplers since 2003. We supply trim carpenters, cabinet shops, and upholsterers in USA, Germany, Australia, Canada and 50+ countries. All staplers are die-cast aluminum with 360° exhaust for finish work.

Need 9040 stapler? Get a quote from KYA today.

Contact Us English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa