16 Gauge 7/16" Medium Crown Staple Gun N851

![7/16 Crown Heavy Duty 16GA N851 Medium Crown Stapler - KYA Fasteners]()

KYA Fasteners, a 20+ year factory, manufactures the N851 16GA medium crown stapler for sheathing, flooring, crates. 7/16" crown, 25–50mm leg, 160-staple magazine. Balanced 2.35kg aluminum body. Exported to USA, Canada, UK, Australia and 50+ countries.

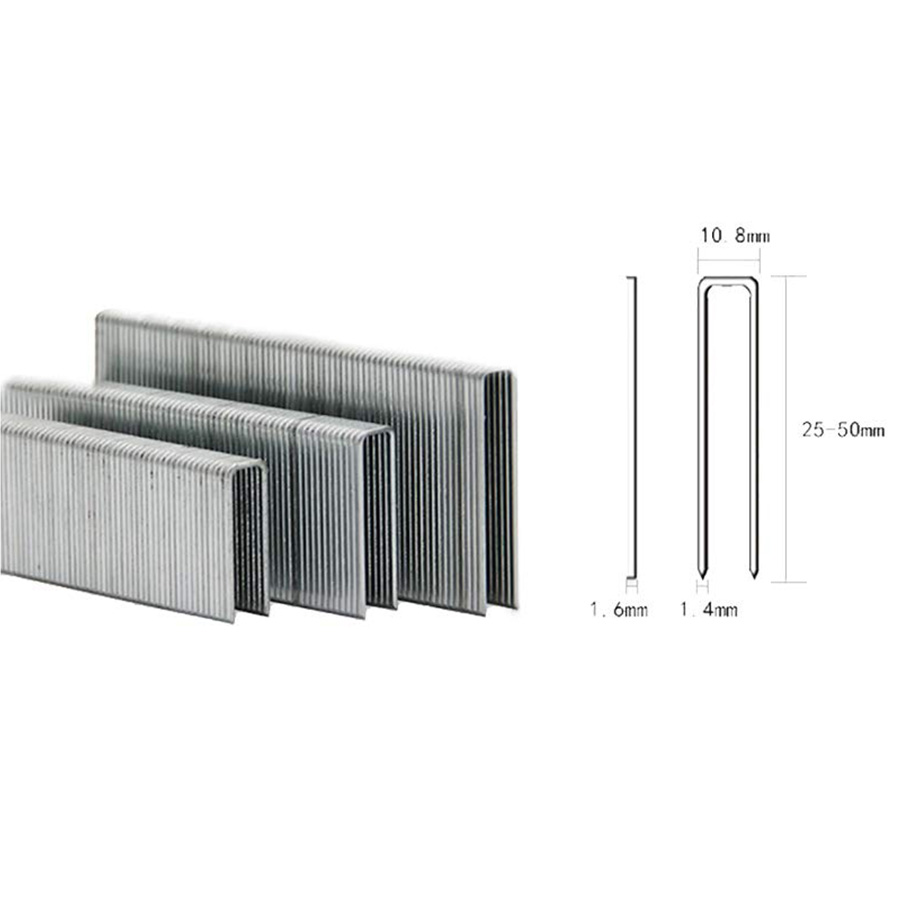

![Medium Crown Series 16GA 7/16 Crown Staples for N851]()

Why Choose KYA N851 Medium Crown Stapler?

Extra-large – 160 staples, max productivity

Cam-lock jam clear — 5-second fix

Aluminum body — 2.35kg durable

360° exhaust — keeps air away

Global shipping: USA, EU, AU, CA in 20–30 days

Request a Quote

Product Specifications

N851 Stapler Specs

| Parameter | Specification |

| Model | KYA-N851 |

| Gauge | 16 GA |

| Crown | 7/16" (10.8mm) |

| Staple Leg | 25–50mm (1"–2") |

| Wire Size | 1.6×1.4mm |

| Magazine Capacity | 160 staples |

| Operating Pressure | 70–120 PSI (5–8.3 bar) |

| Weight | 2.35kg (5.17 lbs) |

| Dimensions | 350×100×320mm |

Request a Quote Features

N851 Stapler Features

160-staple magazine — max capacity

Cam-lock jam release — 5-second fix

Aluminum body — 2.35kg durable

360° exhaust — directs air away

Rubber grip — comfort & control

Built-in air filter — faster cycles

Applications

Where Is N851 Stapler Used?

Subflooring – plywood to joists

Wall sheathing – OSB, panels

Crate & pallet – heavy packaging

Furniture frames – bracing, joints

Vinyl siding – secure hold

![N851 in Subflooring Work]() Explore All Staplers

Explore All Staplers Frequently Asked Questions

N851 Stapler FAQ

What staples does N851 use?

16GA 7/16" crown — 25–50mm leg, 1.6×1.4mm wire.

Best for subflooring?

Yes — 10.8mm crown + 160-staple mag for fast, secure hold.

Magazine capacity?

160 staples — largest in class, less downtime.

Jam clearing?

Cam-lock system — clear in 5 seconds.

Air pressure?

70–120 PSI (5–8.3 bar) — powerful penetration.

Ask a Question Troubleshooting Guide

Common N851 Issues & Fixes

| Issue | Cause | Solution |

| Air leak at cylinder cap (tool off) | Loose head valve seal | Replace head valve piston set |

| Worn o-ring under cap | Replace o-ring/gasket |

| Air leak at trigger (tool off) | Damaged trigger o-ring | Replace o-ring |

| Dirty trigger valve | Clean valve |

| Worn trigger stem | Replace stem |

| Tool jams | Bent driver | Replace driver |

| Worn nose | Replace driver guide |

| Bent guide cover | Replace cover |

About KYA Fasteners

KYA Fasteners – N851 Stapler Factory

Since 2003, KYA Fasteners has produced the N851 16GA medium crown stapler for flooring installers, framers, crate builders in USA, Canada, UK, Australia and 50+ countries. Uses 7/16" crown staples for high-volume jobs.

Need the N851 stapler? Get a quote from KYA today.

Contact Us English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa