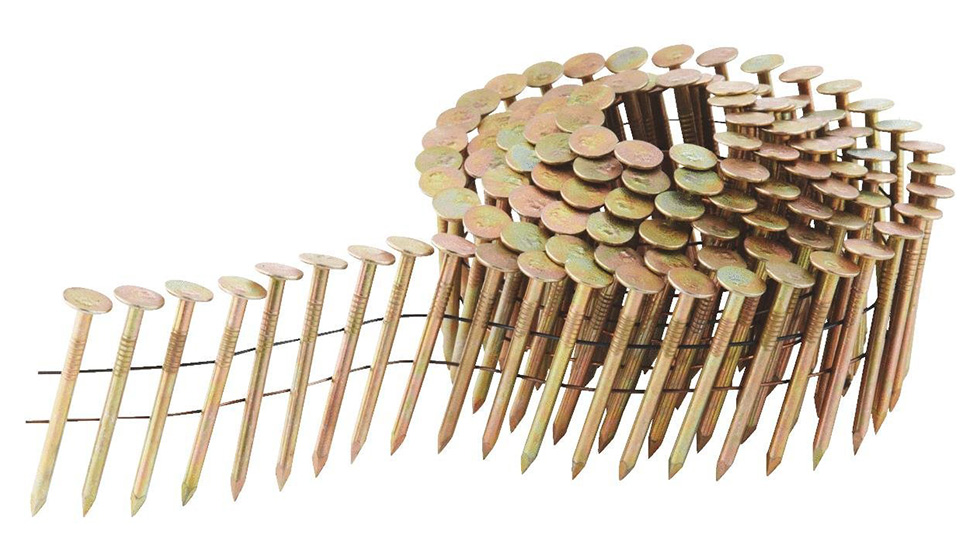

CRN45 Pneumatic Coil Roofing Nailer – 15° Wire Collated

![120 Nail Magazine KYA CRN45 Coil Roofing Nailer - Lightweight & Powerful]()

KYA Fasteners, a 20+ year factory, produces the CRN45 pneumatic coil roofing nailer for asphalt shingles, insulation boards, fiber cement siding. Ultra-light aluminum body (2.58kg), 120-nail magazine, drives 3/4"–1¾" × .120" 15° wire coil nails. Compatible with Bostitch RN46, Hitachi NV45AB2, Senco 455XP, Max CN445R2. Exported to USA, Canada, UK, Australia and 50+ countries.

![.120 Shank 15° Wire Collated Roofing Nails]()

Why Choose KYA CRN45 Coil Roofing Nailer?

Ultra-light — 2.58kg aluminum body

120-nail magazine — less reload

360° exhaust — clean & quiet

Depth control — flush drive

Global shipping: USA, EU, AU, CA in 15–25 days

Request a Quote

Product Specifications

CRN45 Technical Specs

| Parameter | Specification |

| Model | CRN45 |

| Weight | 2.58 kg (5.67 lbs) |

| Dimensions | 313 × 116 × 271 mm |

| Operating Pressure | 70–120 PSI (5–8.3 bar) |

| Magazine Capacity | 120 nails |

| Nail Type | 15° Wire Collated Roofing Nails |

| Nail Length | ¾"–1¾" (19–45 mm) |

| Shank Diameter | .120" (3.05 mm) |

| Compatible With | Bostitch RN46, Hitachi NV45AB2, Senco 455XP, Max CN445R2 |

![Fast & Flush CRN45 in Asphalt Shingle Roofing]() Request a Quote

Request a Quote Key Features

CRN45 Performance Features

360° adjustable exhaust — clean workspace

Contact & sequential firing — versatile

Aluminum die-cast body — light & durable

Depth adjustment — flush every time

Side-load magazine — fast reload

Rubber comfort grip — all-day use

Applications

Where Is CRN45 Used?

Asphalt shingles – residential roofing

Fiber cement siding – exterior walls

Insulation boards – sheathing

Roof decking – plywood, OSB

Vinyl siding – light-duty

Explore All Coil Nailers Troubleshooting Guide

Common Issues & Fixes

| Symptom | Cause | Solution |

| Air leak at cap | Loose/worn O-ring | Replace head valve O-ring |

| Weak drive | Low air / worn piston | Check pressure / replace piston O-ring |

| Jams | Bent driver / wrong nails | Replace driver / use .120" 15° nails |

| No fire | Trigger jam / low air | Clean trigger / check 70+ PSI |

KYA Advantages

Why Buy from KYA?

MAX compatible parts — easy repair

Full spare parts stock — fast shipping

Hardwood power — 120 PSI max

MOQ 1 unit — no minimum

3-year warranty — pro-grade

Frequently Asked Questions

CRN45 FAQ

What nails does it use?

15° wire collated — ¾"–1¾", .120" shank.

Bostitch RN46 compatible?

Yes — full parts & nail compatibility.

Weight?

2.58kg — lightest in class.

Warranty?

3 years — pro-grade support.

Ask a Question About KYA Fasteners

KYA Fasteners – Pneumatic Nailer Factory

Since 2003, KYA Fasteners has produced CRN45 coil roofing nailers for roofing & siding contractors in USA, Canada, UK, Australia and 50+ countries. Lightweight, powerful, MAX-compatible.

Export: 50+ countries

MOQ: 1 unit

OEM: Custom color/logo

Lead time: 15–25 days

Need CRN45 roofing nailer? Get a quote from KYA today.

Contact Us English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa