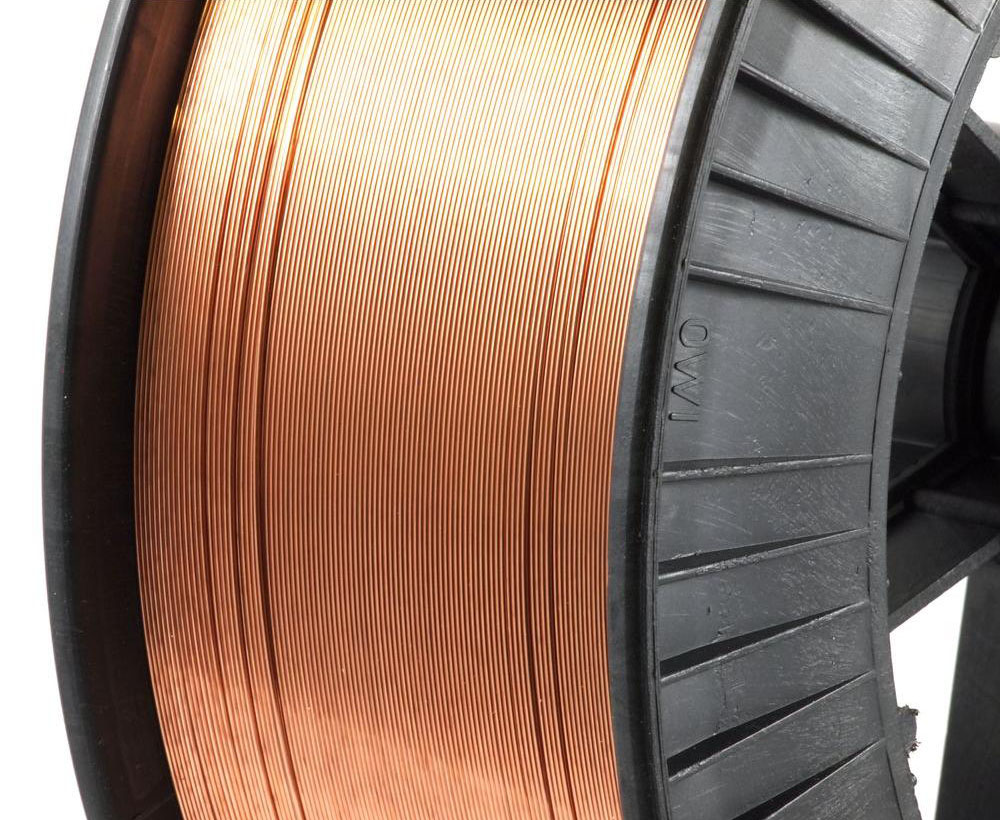

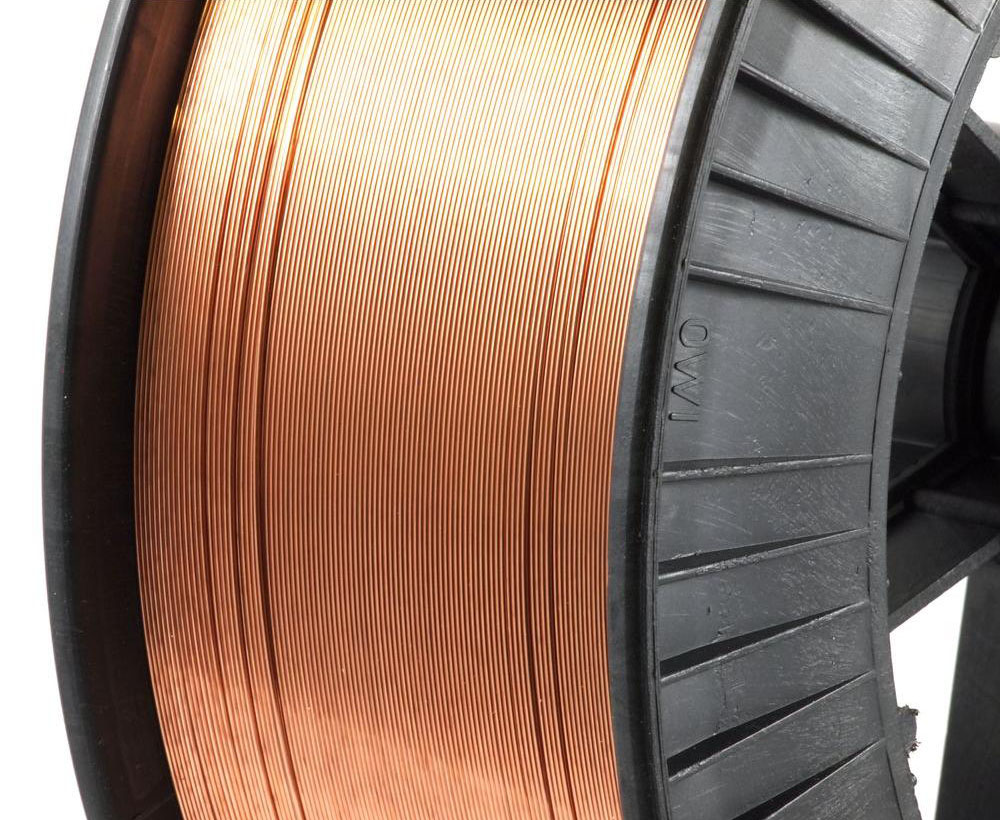

Name: CO2 welding wire,SG2, Gas shielded welding wire ER50-6,AWS ER70S-6, DIN SG2, JIS YGW12;

Raw material: Mild steel,Carbon steel.

Surface:Copper coated , copper clad.

Application : Welding of mild steel material,shipb building, Arc welding etc.

Dia: 0.6mm, 0.8mm 0.9mm 1.0mm 1.2mm 1.6mm .

Packing: 5Kg,15Kg 20kg spool, 100~350kg drum, export seaworthy package.

Spool type: D270 or D300 plastic spool, K300 Metal spool.

Notes: Wrapped in the black or white plastic spool, covered with the wax paper, then in PE bag and carton, and lay on pallet.

Gas Shielded Welding Wire ER70S-6 -- Main Characteristics:

1. Low welding costs.

2. High productivity and low electricity consumption.

3. Easy to operate. All-position welding.

4. Very low hydrogen content in the weld and lower nitrogen content. Excellent crack-resistance.

5. Little deformation after welding.

6. Wide applicability. Suitable for welding thin, medium and thick plates.

Chemical Composition of Welding Wire (%):

| C | Mn | Si | S | P | Cu |

| 0.06~0.15 | 1.4~1.85 | 0.8~1.15 | ≤0.035 | ≤0.025 | ≤0.50 |

Example of Chemical Composition of Deposited Metal(%):

| C | Mn | Si | S | P | Cu |

| 0.07 | 1.27 | 0.76 | 0.014 | 0.015 | 0.15 |

Mechanical Properties of Deposited Metal:

| Test Item | Rm(MPa) | ReLRp0.2(Mpa) | A(%) | KV2(J) |

| Guarantee Value | ≥500 | ≥420 | ≥22 | ≥27(-30ºC) |

| General Result | 558 | 472 | 27 | 98 |

Reference Current (DC+):

| Wire Size(mm) | Welding Current(A) | CO2 Flow Rate(L/min) |

| φ0.6 | 50~80 | 10~15 |

| φ0.8 | 50~100 | 15 |

| φ1.0 | 50~220 | 15~20 |

| φ1.2 | 80~350 | 15~25 |

| φ1.6 | 170~550 | 20~25 |

Widely used in the steel structure welding

√ coal mine machinery,

√ ships,

√ engineering machinery,

√ bridges,

√ pressure vessels,

√ building construction

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Беларуская мова

guarani

Chichewa